Книги

Centennial Perspective

C.Owers

Beardmore Aircraft of WW1

152

C.Owers - Beardmore Aircraft of WW1 /Centennial Perspective/ (69)

Beardmore W.B.I

In 1916 the Admiralty allowed Lt George Tilghman-Richards, RNVR, to resign his commission and join Beardmores as that firm’s chief designer. Tilghman-Richards had experience with aircraft construction, having helped with the Lee-Richards Annular Monoplane. He had been working at Beardmores as an Inspector of Naval Aircraft, and when the Admiralty decided to encourage those firms that were building aircraft for them to look at developing their own designs, a course that Beardmore was willing to follow, it was natural that Richards should work for Beardmore.

In December 1914, the Admiralty issued a specification for a large bombing machine powered by two engines capable of carrying 6 x 112-lb bombs. This was to lead to the Handley-Page O/100. Due to the problems that had to be worked out in order to get the O/100 into production, the Admiralty issued a specification for a single-engined bomber that was intended to attack its targets silently by using a long glide approach with engine off. The machine had to carry 8 x 112-lb bombs. These requirements meant that all designs submitted featured extended wings and low wing-loading. The following companies were invited to submit designs and the winner was promised a substantial order. Avro submitted their 528 bomber design, Grahame-White their Type 18, Short Brothers their Bomber, J Samuel White the Wight Type 840, and Beardmore the W.B.I.

The first original Beardmore design was the W.B.I, (W.B. for William Beardmore),‘The Experimental Bomb Dropper’ was built to meet the requirements of the Admiralty Competition of 1915-1916. Contract No. A.S.7123 was raised to cover one prototype and it received RNAS serial No. N525.2 Reports from the Admiralty’s D (Design) Section refer to the Beardmore Competition machine:

W/E 02 September 1916:

Armstrong Triplane and Beardmore Competition Machine - Stresses started on but abandoned for want of particulars.

Beardmore Competition. Preliminary stability investigation made.

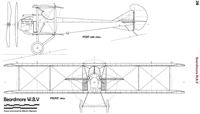

The W.B.I was a large single engine biplane with heavily staggered three-bay wings of high aspect ratio. The W.B.I was designed to have a gliding ratio of about 1 in 15.

The engine was to be either the 230-hp Beardmore Adriatic or the 240-hp Sunbeam. It appears that the Adriatic may never have been fitted to the machine. The Sunbeam engine was carefully cowled to give a good streamline although it would not compensate for the complex and clumsy looking undercarriage and large radiators. No external radiator is visible in photographs of the first version of the W.B.I, leading to the conclusion that there may have been an internal radiator fed with air from the hollow-fronted airscrew spinner.

The pilot and observer/gunner were located behind the wings. The observer was also the bomb-aimer. He had an opening in the floor through which he could aim his bombs. The pilot and observer were separated with the observer seated behind the pilot to starboard, and the pilot seated to port in the wide fuselage. They could communicate by a system similar to a ship’s telegraph. The observer had a Lewis gun on a ring-mounting at his cockpit.

Six 110-lb bombs were carried inside the fuselage on Skeleton Channel carriers, three abreast. When released, the weight of the bombs opened the bomb bay doors that were closed by Sandow elastic cord. The cumbersome undercarriage was in two parts so that it did not interfere with the bomb dropping. It used four large wheels at the rear and four smaller wheels at the front, such that the machine was level when at rest. This was to cause trouble as will be related.

As first rolled out the W.B.I had N-type interplane struts, however, it crashed at Inchinnan during its first trial on 20 September 1916. The pilot was Beardmore’s test pilot Duncan Jones. The aircraft was lacking in directional control and during a hurried landing the undercarriage collapsed. Rebuilt, it had conventional struts with cross bracing. Sent to Cranwell it was erected and delivered for gunnery training on 8 June 1917, and made its first flight since arriving the same day but the engined was not performing satisfactorily. Re-engined with a 240-hp Sunbeam it had a second crash. On landing at Cranwell on 5 July 1917, while being flown by Wing-Cdr R.E.C. Peirse, the aircraft kept rolling with its tail up and crashed into two B.E.2c that were parked on the tarmac. The aircraft had no brakes, the tail skid acted as the brake and with the aircraft held up on its landing gear, it just kept rolling. Repaired, it was crashed beyond repair on 18 September, and deleted as wrecked on 8 October 1917.

A proposed development, the W.B.IA long-distance bomber, with a 500-hp B.H.P. Atlantic engine and larger wings of 70 feet span remained a project only. The pilot and observer are placed very much in the rear of the main plane, the pilot being midway between the main and tailplanes and the observer is immediately in advance of the fixed fin which emerges from the fairing round the observers cockpit. The Handley-Page O/100 became available and could carry could carry six times the bomb load of the W.B.I and there was no prospect of the W.B.I entering production.

W.B.I Specifications

Source Jane's 1919 J.M. Bruce Data

Span 61 ft 6 in 61 ft 6 in

Length 32 ft 10 in 32 ft 10 in

Height 14 ft 9 in 14 ft 9 in

Chord 7 ft 7 ft

Gap 7 ft 7 ft

Span tail 18 ft 18 ft

Airscrew dia 10 ft 6 in 10 ft 6 in

Areas in ft2

Wings 796 -

Ailerons 113.26 -

Tailplane 106 -

Elevators 40 -

Fin 14.2 -

Rudder 20 -

Weights in lbs

Empty 3,410 3,410

Disposable load 1,100 1,100

Fuel & Oil 1,090 1,090

Loaded 5,600 5,600

Performance

Speed in mph

Ground level 91 91

landing 48 -

Climb

to 5,000 ft 26 min 26 min

to 10,000 ft 44 mins 44 mins

Endurance in hrs 7.3 7.3

Capacities in gals 137 -

Petrol - 137

Engine 230-hp Beardmore Adriatic 230-hp Beardmore

In 1916 the Admiralty allowed Lt George Tilghman-Richards, RNVR, to resign his commission and join Beardmores as that firm’s chief designer. Tilghman-Richards had experience with aircraft construction, having helped with the Lee-Richards Annular Monoplane. He had been working at Beardmores as an Inspector of Naval Aircraft, and when the Admiralty decided to encourage those firms that were building aircraft for them to look at developing their own designs, a course that Beardmore was willing to follow, it was natural that Richards should work for Beardmore.

In December 1914, the Admiralty issued a specification for a large bombing machine powered by two engines capable of carrying 6 x 112-lb bombs. This was to lead to the Handley-Page O/100. Due to the problems that had to be worked out in order to get the O/100 into production, the Admiralty issued a specification for a single-engined bomber that was intended to attack its targets silently by using a long glide approach with engine off. The machine had to carry 8 x 112-lb bombs. These requirements meant that all designs submitted featured extended wings and low wing-loading. The following companies were invited to submit designs and the winner was promised a substantial order. Avro submitted their 528 bomber design, Grahame-White their Type 18, Short Brothers their Bomber, J Samuel White the Wight Type 840, and Beardmore the W.B.I.

The first original Beardmore design was the W.B.I, (W.B. for William Beardmore),‘The Experimental Bomb Dropper’ was built to meet the requirements of the Admiralty Competition of 1915-1916. Contract No. A.S.7123 was raised to cover one prototype and it received RNAS serial No. N525.2 Reports from the Admiralty’s D (Design) Section refer to the Beardmore Competition machine:

W/E 02 September 1916:

Armstrong Triplane and Beardmore Competition Machine - Stresses started on but abandoned for want of particulars.

Beardmore Competition. Preliminary stability investigation made.

The W.B.I was a large single engine biplane with heavily staggered three-bay wings of high aspect ratio. The W.B.I was designed to have a gliding ratio of about 1 in 15.

The engine was to be either the 230-hp Beardmore Adriatic or the 240-hp Sunbeam. It appears that the Adriatic may never have been fitted to the machine. The Sunbeam engine was carefully cowled to give a good streamline although it would not compensate for the complex and clumsy looking undercarriage and large radiators. No external radiator is visible in photographs of the first version of the W.B.I, leading to the conclusion that there may have been an internal radiator fed with air from the hollow-fronted airscrew spinner.

The pilot and observer/gunner were located behind the wings. The observer was also the bomb-aimer. He had an opening in the floor through which he could aim his bombs. The pilot and observer were separated with the observer seated behind the pilot to starboard, and the pilot seated to port in the wide fuselage. They could communicate by a system similar to a ship’s telegraph. The observer had a Lewis gun on a ring-mounting at his cockpit.

Six 110-lb bombs were carried inside the fuselage on Skeleton Channel carriers, three abreast. When released, the weight of the bombs opened the bomb bay doors that were closed by Sandow elastic cord. The cumbersome undercarriage was in two parts so that it did not interfere with the bomb dropping. It used four large wheels at the rear and four smaller wheels at the front, such that the machine was level when at rest. This was to cause trouble as will be related.

As first rolled out the W.B.I had N-type interplane struts, however, it crashed at Inchinnan during its first trial on 20 September 1916. The pilot was Beardmore’s test pilot Duncan Jones. The aircraft was lacking in directional control and during a hurried landing the undercarriage collapsed. Rebuilt, it had conventional struts with cross bracing. Sent to Cranwell it was erected and delivered for gunnery training on 8 June 1917, and made its first flight since arriving the same day but the engined was not performing satisfactorily. Re-engined with a 240-hp Sunbeam it had a second crash. On landing at Cranwell on 5 July 1917, while being flown by Wing-Cdr R.E.C. Peirse, the aircraft kept rolling with its tail up and crashed into two B.E.2c that were parked on the tarmac. The aircraft had no brakes, the tail skid acted as the brake and with the aircraft held up on its landing gear, it just kept rolling. Repaired, it was crashed beyond repair on 18 September, and deleted as wrecked on 8 October 1917.

A proposed development, the W.B.IA long-distance bomber, with a 500-hp B.H.P. Atlantic engine and larger wings of 70 feet span remained a project only. The pilot and observer are placed very much in the rear of the main plane, the pilot being midway between the main and tailplanes and the observer is immediately in advance of the fixed fin which emerges from the fairing round the observers cockpit. The Handley-Page O/100 became available and could carry could carry six times the bomb load of the W.B.I and there was no prospect of the W.B.I entering production.

W.B.I Specifications

Source Jane's 1919 J.M. Bruce Data

Span 61 ft 6 in 61 ft 6 in

Length 32 ft 10 in 32 ft 10 in

Height 14 ft 9 in 14 ft 9 in

Chord 7 ft 7 ft

Gap 7 ft 7 ft

Span tail 18 ft 18 ft

Airscrew dia 10 ft 6 in 10 ft 6 in

Areas in ft2

Wings 796 -

Ailerons 113.26 -

Tailplane 106 -

Elevators 40 -

Fin 14.2 -

Rudder 20 -

Weights in lbs

Empty 3,410 3,410

Disposable load 1,100 1,100

Fuel & Oil 1,090 1,090

Loaded 5,600 5,600

Performance

Speed in mph

Ground level 91 91

landing 48 -

Climb

to 5,000 ft 26 min 26 min

to 10,000 ft 44 mins 44 mins

Endurance in hrs 7.3 7.3

Capacities in gals 137 -

Petrol - 137

Engine 230-hp Beardmore Adriatic 230-hp Beardmore

The W.B.I readying for take-off. Note the pilot's position. His view over the nose must have been minimal.

G.Tighman-Richards with G.T. Richards (in flying helmet) pose with the W.B.I. Richards would test fly virtually all the Beardmore company's aircraft. Note that the W.B.I. has N interplane struts.

Another view of the W.B.I, this time showing the open-fronted spinner favored by G Tighman-Richards, Beardmore's chief designer.

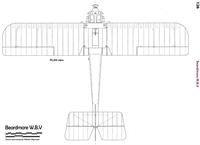

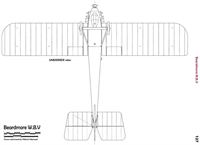

Beardmore W.B.II Fighter/Reconnaissance Biplane

G. Tilghman-Richards was chief designer at Beardmore & Co Ltd when the firm set up its own design office. He sought to design a better aircraft than the B.E.2c that Beardmores were building for the Admiralty. Permission was granted for the company to go ahead with the proposal as a private venture (Works Contract No. 1133). The proposed machine would have a more powerful engine and cleaned-up fuselage.

A report from 9 May 1917, under the section titled: - ‘Machines believed to be under or design or partial construction by various firms,’ listed under Beardmore a 2-seater Fgtr. for Hispano-Suiza engine. This machine was designed some while ago and a Beardmore engine was promised to the Firm if possible by last January. Owing to the shortage of engines it has not been possible to supply this and it is understood that a 200 HP Hispano-Suiza has now been allotted by N.A.D. in order to test out the machine to which we were partially committed.

The design of the W.B.II was originally conceived to use the six-cylinder in-line 160-hp Beardmore engine. It retailed the B.E.2c fin and rudder and the wing structure of the B.E. mainplanes. The fuselage was faired out into a roughly circular cross-section. A large single exhaust port carried the exhaust to a silencer mounted centrally above the upper wing. The position of pilot and observer/gunner was changed from that of the B.E.2c in that the pilot had the front seat. He was given a synchronized Vickers gun and the rear gunner had a Lewis gun on a ring mount. As noted above, the shortage of engines meant that it was early May 1917, before the Air Department of the Admiralty were able to provide an engine, and this was a 200-hp Hispano-Suiza, in order that the machine could be tested. Contract No. AS2864/18 was raised to cover the machine.

The design was changed to accommodate the new engine it being reported that Various points in the installation require attention. This machine will be ready for test in three weeks. A later report noted that all alterations asked for had been carried out and the machine should be ready to fly within the week.

The W.B.II appeared with a large open-front spinner to the four-bladed airscrew. Twin exhaust stacks were fitted and two flat tube radiators were fixed longitudinally with v-struts of the cabane under top plane. Twin synchronized Vickers guns were now provided for the pilot. The observer’s gun ring was mounted on the top longerons. The rear Lewis gun was on a Beardmore swivel mount. This ‘Witch’s Broomstick’ was designed by G Tilghman-Richards and combined a seat mounted on a pillar to which extension the Lewis gun was attached. This mount is illustrated in H.F. King’s book on British aircraft armament.

The pilot was positioned immediately behind the engine and fuel tanks under the top plane. The observer was immediately behind the pilot. Dual control was fitted for us of the observer if necessary. The landing gear was streamlined steel tube.

The machine made its first flight under the hands of A. Dukinfield Jones on 30 August 1917. The dismantled machine was sent to Martlesham Heath in early October, arriving on the 3rd. Report No. A/70 noted that a flight was attempted but owing to unsatisfactory running of the engine it was only possible to stay in the air for a few minutes, however, this was enough for a two page report to be compiled listing the aircraft’s deficiencies as a fighter, from a gunner s point of view.

The gunner’s cockpit was far from ideal. The greatest depth from the top of the ring mount is only 34 inches, the average being 33 inches: this is 4 critical inches short of what is considered to be the minimum for a fighting machine. The fuselage, generally, is very shallow, and the gunner is consequently very exposed to the propeller draught and the possibility of falling out in any violent manoeuvre which virtually reduces his weight, unless he is provided with some form of harness.

The gun mount was designed by Beardmore and had many weak points and is generally considered much inferior to the standard Scarff Ring: the internal diameter of the ring is 28 inches, and therefore the same circumference as a Scarff mount.

The observer’s view was good and the field of fire was about equal to any existing two-seater. The elevator and rudder controls being inside the fuselage is a very good feature, and might be well copied in all fighting machines.

What was most interesting about the W.B.II’s armament was the Beardmore-Richards mounting in the gunner’s cockpit which was called The Witch’s Broomstick. This comprised a central member to which was attached the gunner’s seat. This could be locked at any desired height and the gunner could lock the device at any position on the guide ring. The upper end carried the Lewis gun. The gun could be locked in any position relative to the central member. When displaced laterally, the field of fire was extended 15° past the centre line of the fuselage.

The pilot’s view was considered to be about the same as that of the De Havilland D.H.9, and can therefore be taken as fairly good, but considerably worse than such a machine as a Bristol Fighter whole top plane is almost level with the pilot’s head. The radiator impaired the pilot’s forward view. The pilot and observer are placed close together as they should be.

In conclusion, without performance figures, it was considered that the machine was at a great disadvantage compared with other up-to-date fighting two-seater. The shallowness of the fuselage and its low setting in relation to the wings leaves the observer very exposed when fighting and without any opportunity of bringing his gun to fire on the same mark as the pilot’s fixed guns. For any proposed two-seater fighting machine these two points are considered of the first importance.

During testing the airscrew came off, holding up trials, and a fuel tank burst. The machine was returned to Beardmores on 19 November 1917, for modifications.

Returning to Martlesham Heath on 2 December, it was tested that month and Report No. M.147b was issued for Beardmore aircraft No. 1133.

The Report made the following observations:

The tailplane was adjustable in flight. The rear Lewis gun was on a Beardmore swivel mount.

Armament was twin synchronized Vickers guns and one Lewis gun for observer on turret mounting.

The two 21-gallon fuel tanks were situated between engine and the pilot, with a streamlined 4 1/2 gallon oil tank suspended below the engine. It was impossible to remove the tanks without first removing the guns and radiator.

Starting was easy. Get away time was 5 minutes.

Stability longitudinally and laterally was Stable. Controllability longitudinally was Good, laterally - Fair; directionally - Good but heavy. Manoeuvreability was only Average for a machine of this class.

Taxi-ing was good. Landing at an ordinary aerodrome was easy. The machine had a flat gliding angle. Although it had a non-adjustable rudder bar, the machine was not tiring to fly.

Other comments noted that there was no armoring for protection from ground fire, and that it was impossible to reach the engine air pipe taps when the seat belt was done up. The water pipe from the top of the engine to the radiator also needed supporting.

The machine had been sent back to the manufacturers who have carried out several modifications. The engine has been moved forward and is now very accessible and can be easily installed or dismantled. The magnetos are also easily accessible through ports and the whole cowling can be removed, in a short time. The cowl on the propeller has been replaced by streamline cowling around the engine.

Further the Gunner’s cockpit has been raised 5 1/2" which gives plenty of depth in the gunner’s cockpit and improved the field of fire. Aluminium petrol tanks have been replaced by steel tanks.

These alterations have improved the machine a good deal, but it is not considered the performance of the machine is good enough to warrant its production as a new type instead of or in addition to the Bristol Fighter. A Bristol Fighter with 200 Hispano suiza (sic) engine has not been tested at this Station but it is fairly certain that its performance would not fall below that given above for the Beardmore Fighter.

With a performance not better than existing types in production and using an engine that was in demand for the S.E.5a fighter, it is no wonder that the machine was not selected for production. When its trials were completed, it was taken over by the RNAS and sent to the Isle of Grain on 17 December 1917, and apparently flown there.

Beardmore proposed the W.B.IIA with a 230-hp B.H.P. engine. Span was 34 feet 6 in and length was 27 feet 7 in. It remained a paper project.

The Aeroplane reported that Beardmore were going to exhibit a W.B.II two-seat sporting and touring machine fitted with a 160-hp engine at the 1920 Olympia Show. It was thought to be eminently suited for its intended purpose or for light mail carrying. Another machine was expected but the engine was not specified. In an attempt to utilize the design, Beardmore produced two mail-carrying version of the design in 1920. These had a 230-hp B.H.P. engine and were designated W.B.IIB. Two such aircraft were given civil registrations G-EARX and G-EARY and took part in the Air Ministry’s civil aircraft competition held at Martlesham Heath in August 1920. A short-lived air-mail service was started by the Beardmore company flying with these machines between Renfrew and London. They were likewise unsuccessful in the post-war environment.

Beardmore W.B.2 Specifications

Source 1 2 3 4

Span 34 ft 10 in 34 ft 10 in 34 ft 10 in 34 ft 10 ini

Length 27 ft 3 in 26 ft 10 in 26 ft 10 in 27 ft 7 in .

Height 10 ft 11 in 10 ft 10 ft 10 ft 11 in

Chord 5 ft 6 in - 5 ft 6 in 5 ft 6 in

Dihedral - - 1 1/2° -

Incidence - - 1 1/2° -

Gap - - 5 ft 6 in 5 ft 6 in

Stagger - - 2 ft 0 in -

Track - - 5 ft 0 in -

Tyres - 750 x125 - -

Span tailplane 13 ft - - -

Airscrew - Lang D.R. C.L/3500 A Lang L/14104 -

Pitch 1186 2975 mm 9 ft 9 in -

Diameter 9 ft 2905 mm 9 ft 6.5 in -

Areas in ft2

Wings 354 - 354 354

Ailerons 64 - 64 -

Tail - - 27.5 -

Elevators 21 - 20.2 -

Rudder 11.5 - 11.5 -

Fin 6 - 6 -

Weights in lbs

Empty 1,765 1,765 - 1,751

Twin Vickers - 70 70 -

Ammunition - 56 - -

Lewis gun - 16 16 -

Ammunition - 32 - -

Dead weight - 11 99 -

Crew - 360 360 -

Total military load - 545 545 -

Fuel (42 gal) Oil (4 1/2 gal) - 340 340 -

Useful load - - - 180

Total 2,650 2,650 2,650 2,516

Capacities in gals

Fuel 41.5 42 - 50

Oil - 4 1/2 - -

Water - 8 - -

Speed in mph at

Ground level 120 - - 10.7

10,000 ft 111 111 1/2 - -

13,000 ft - 107 - -

Landing 50 - - 55

Climb to

1,000 ft - 1 min 15 - -

2,000 ft - 2 min 35 - -

3,000 ft - 4 min 00 - -

4,000 ft - 5 min 25 - -

5,000 ft 7 min 7 min 00 - -

6,000 ft - 8 min 40 - -

7,000 ft - 10 min 30 - -

8,000 ft - 12 min 30 - -

9,000 ft - 14 min 40 - -

10,000 ft 15 min 17 min 05 - 25 min

11,000 ft - 19 min 45 - -

12,000 ft - 22 min 40 - -

13,000 ft - 26 min 10 - -

14,000 ft - 30 min 10 - -

Duration in hours 2.8 - - 4

Engine - Peugeot Hispano-Suiza No.115014 - 160-hp Beardmore

Notes:

1. In a tabulation in its 14 July 1920 issue, The Aeroplane gives a span of 35 ft 0 in and describes the W.B.2 as a three-seater.

Source:

1. Jane’s All the World’s Aircraft, 1919. Arco Publishing USA 1990.

2. Report M.147B.

3. Aeroplane Data Book.

4. Aeronautical Engineering supplement to The Aeroplane, 14 July 1920.

G. Tilghman-Richards was chief designer at Beardmore & Co Ltd when the firm set up its own design office. He sought to design a better aircraft than the B.E.2c that Beardmores were building for the Admiralty. Permission was granted for the company to go ahead with the proposal as a private venture (Works Contract No. 1133). The proposed machine would have a more powerful engine and cleaned-up fuselage.

A report from 9 May 1917, under the section titled: - ‘Machines believed to be under or design or partial construction by various firms,’ listed under Beardmore a 2-seater Fgtr. for Hispano-Suiza engine. This machine was designed some while ago and a Beardmore engine was promised to the Firm if possible by last January. Owing to the shortage of engines it has not been possible to supply this and it is understood that a 200 HP Hispano-Suiza has now been allotted by N.A.D. in order to test out the machine to which we were partially committed.

The design of the W.B.II was originally conceived to use the six-cylinder in-line 160-hp Beardmore engine. It retailed the B.E.2c fin and rudder and the wing structure of the B.E. mainplanes. The fuselage was faired out into a roughly circular cross-section. A large single exhaust port carried the exhaust to a silencer mounted centrally above the upper wing. The position of pilot and observer/gunner was changed from that of the B.E.2c in that the pilot had the front seat. He was given a synchronized Vickers gun and the rear gunner had a Lewis gun on a ring mount. As noted above, the shortage of engines meant that it was early May 1917, before the Air Department of the Admiralty were able to provide an engine, and this was a 200-hp Hispano-Suiza, in order that the machine could be tested. Contract No. AS2864/18 was raised to cover the machine.

The design was changed to accommodate the new engine it being reported that Various points in the installation require attention. This machine will be ready for test in three weeks. A later report noted that all alterations asked for had been carried out and the machine should be ready to fly within the week.

The W.B.II appeared with a large open-front spinner to the four-bladed airscrew. Twin exhaust stacks were fitted and two flat tube radiators were fixed longitudinally with v-struts of the cabane under top plane. Twin synchronized Vickers guns were now provided for the pilot. The observer’s gun ring was mounted on the top longerons. The rear Lewis gun was on a Beardmore swivel mount. This ‘Witch’s Broomstick’ was designed by G Tilghman-Richards and combined a seat mounted on a pillar to which extension the Lewis gun was attached. This mount is illustrated in H.F. King’s book on British aircraft armament.

The pilot was positioned immediately behind the engine and fuel tanks under the top plane. The observer was immediately behind the pilot. Dual control was fitted for us of the observer if necessary. The landing gear was streamlined steel tube.

The machine made its first flight under the hands of A. Dukinfield Jones on 30 August 1917. The dismantled machine was sent to Martlesham Heath in early October, arriving on the 3rd. Report No. A/70 noted that a flight was attempted but owing to unsatisfactory running of the engine it was only possible to stay in the air for a few minutes, however, this was enough for a two page report to be compiled listing the aircraft’s deficiencies as a fighter, from a gunner s point of view.

The gunner’s cockpit was far from ideal. The greatest depth from the top of the ring mount is only 34 inches, the average being 33 inches: this is 4 critical inches short of what is considered to be the minimum for a fighting machine. The fuselage, generally, is very shallow, and the gunner is consequently very exposed to the propeller draught and the possibility of falling out in any violent manoeuvre which virtually reduces his weight, unless he is provided with some form of harness.

The gun mount was designed by Beardmore and had many weak points and is generally considered much inferior to the standard Scarff Ring: the internal diameter of the ring is 28 inches, and therefore the same circumference as a Scarff mount.

The observer’s view was good and the field of fire was about equal to any existing two-seater. The elevator and rudder controls being inside the fuselage is a very good feature, and might be well copied in all fighting machines.

What was most interesting about the W.B.II’s armament was the Beardmore-Richards mounting in the gunner’s cockpit which was called The Witch’s Broomstick. This comprised a central member to which was attached the gunner’s seat. This could be locked at any desired height and the gunner could lock the device at any position on the guide ring. The upper end carried the Lewis gun. The gun could be locked in any position relative to the central member. When displaced laterally, the field of fire was extended 15° past the centre line of the fuselage.

The pilot’s view was considered to be about the same as that of the De Havilland D.H.9, and can therefore be taken as fairly good, but considerably worse than such a machine as a Bristol Fighter whole top plane is almost level with the pilot’s head. The radiator impaired the pilot’s forward view. The pilot and observer are placed close together as they should be.

In conclusion, without performance figures, it was considered that the machine was at a great disadvantage compared with other up-to-date fighting two-seater. The shallowness of the fuselage and its low setting in relation to the wings leaves the observer very exposed when fighting and without any opportunity of bringing his gun to fire on the same mark as the pilot’s fixed guns. For any proposed two-seater fighting machine these two points are considered of the first importance.

During testing the airscrew came off, holding up trials, and a fuel tank burst. The machine was returned to Beardmores on 19 November 1917, for modifications.

Returning to Martlesham Heath on 2 December, it was tested that month and Report No. M.147b was issued for Beardmore aircraft No. 1133.

The Report made the following observations:

The tailplane was adjustable in flight. The rear Lewis gun was on a Beardmore swivel mount.

Armament was twin synchronized Vickers guns and one Lewis gun for observer on turret mounting.

The two 21-gallon fuel tanks were situated between engine and the pilot, with a streamlined 4 1/2 gallon oil tank suspended below the engine. It was impossible to remove the tanks without first removing the guns and radiator.

Starting was easy. Get away time was 5 minutes.

Stability longitudinally and laterally was Stable. Controllability longitudinally was Good, laterally - Fair; directionally - Good but heavy. Manoeuvreability was only Average for a machine of this class.

Taxi-ing was good. Landing at an ordinary aerodrome was easy. The machine had a flat gliding angle. Although it had a non-adjustable rudder bar, the machine was not tiring to fly.

Other comments noted that there was no armoring for protection from ground fire, and that it was impossible to reach the engine air pipe taps when the seat belt was done up. The water pipe from the top of the engine to the radiator also needed supporting.

The machine had been sent back to the manufacturers who have carried out several modifications. The engine has been moved forward and is now very accessible and can be easily installed or dismantled. The magnetos are also easily accessible through ports and the whole cowling can be removed, in a short time. The cowl on the propeller has been replaced by streamline cowling around the engine.

Further the Gunner’s cockpit has been raised 5 1/2" which gives plenty of depth in the gunner’s cockpit and improved the field of fire. Aluminium petrol tanks have been replaced by steel tanks.

These alterations have improved the machine a good deal, but it is not considered the performance of the machine is good enough to warrant its production as a new type instead of or in addition to the Bristol Fighter. A Bristol Fighter with 200 Hispano suiza (sic) engine has not been tested at this Station but it is fairly certain that its performance would not fall below that given above for the Beardmore Fighter.

With a performance not better than existing types in production and using an engine that was in demand for the S.E.5a fighter, it is no wonder that the machine was not selected for production. When its trials were completed, it was taken over by the RNAS and sent to the Isle of Grain on 17 December 1917, and apparently flown there.

Beardmore proposed the W.B.IIA with a 230-hp B.H.P. engine. Span was 34 feet 6 in and length was 27 feet 7 in. It remained a paper project.

The Aeroplane reported that Beardmore were going to exhibit a W.B.II two-seat sporting and touring machine fitted with a 160-hp engine at the 1920 Olympia Show. It was thought to be eminently suited for its intended purpose or for light mail carrying. Another machine was expected but the engine was not specified. In an attempt to utilize the design, Beardmore produced two mail-carrying version of the design in 1920. These had a 230-hp B.H.P. engine and were designated W.B.IIB. Two such aircraft were given civil registrations G-EARX and G-EARY and took part in the Air Ministry’s civil aircraft competition held at Martlesham Heath in August 1920. A short-lived air-mail service was started by the Beardmore company flying with these machines between Renfrew and London. They were likewise unsuccessful in the post-war environment.

Beardmore W.B.2 Specifications

Source 1 2 3 4

Span 34 ft 10 in 34 ft 10 in 34 ft 10 in 34 ft 10 ini

Length 27 ft 3 in 26 ft 10 in 26 ft 10 in 27 ft 7 in .

Height 10 ft 11 in 10 ft 10 ft 10 ft 11 in

Chord 5 ft 6 in - 5 ft 6 in 5 ft 6 in

Dihedral - - 1 1/2° -

Incidence - - 1 1/2° -

Gap - - 5 ft 6 in 5 ft 6 in

Stagger - - 2 ft 0 in -

Track - - 5 ft 0 in -

Tyres - 750 x125 - -

Span tailplane 13 ft - - -

Airscrew - Lang D.R. C.L/3500 A Lang L/14104 -

Pitch 1186 2975 mm 9 ft 9 in -

Diameter 9 ft 2905 mm 9 ft 6.5 in -

Areas in ft2

Wings 354 - 354 354

Ailerons 64 - 64 -

Tail - - 27.5 -

Elevators 21 - 20.2 -

Rudder 11.5 - 11.5 -

Fin 6 - 6 -

Weights in lbs

Empty 1,765 1,765 - 1,751

Twin Vickers - 70 70 -

Ammunition - 56 - -

Lewis gun - 16 16 -

Ammunition - 32 - -

Dead weight - 11 99 -

Crew - 360 360 -

Total military load - 545 545 -

Fuel (42 gal) Oil (4 1/2 gal) - 340 340 -

Useful load - - - 180

Total 2,650 2,650 2,650 2,516

Capacities in gals

Fuel 41.5 42 - 50

Oil - 4 1/2 - -

Water - 8 - -

Speed in mph at

Ground level 120 - - 10.7

10,000 ft 111 111 1/2 - -

13,000 ft - 107 - -

Landing 50 - - 55

Climb to

1,000 ft - 1 min 15 - -

2,000 ft - 2 min 35 - -

3,000 ft - 4 min 00 - -

4,000 ft - 5 min 25 - -

5,000 ft 7 min 7 min 00 - -

6,000 ft - 8 min 40 - -

7,000 ft - 10 min 30 - -

8,000 ft - 12 min 30 - -

9,000 ft - 14 min 40 - -

10,000 ft 15 min 17 min 05 - 25 min

11,000 ft - 19 min 45 - -

12,000 ft - 22 min 40 - -

13,000 ft - 26 min 10 - -

14,000 ft - 30 min 10 - -

Duration in hours 2.8 - - 4

Engine - Peugeot Hispano-Suiza No.115014 - 160-hp Beardmore

Notes:

1. In a tabulation in its 14 July 1920 issue, The Aeroplane gives a span of 35 ft 0 in and describes the W.B.2 as a three-seater.

Source:

1. Jane’s All the World’s Aircraft, 1919. Arco Publishing USA 1990.

2. Report M.147B.

3. Aeroplane Data Book.

4. Aeronautical Engineering supplement to The Aeroplane, 14 July 1920.

On the same occasion at Dulmuir, the gunner shows the Tighman-Richard's gun mounting. The pillar to which the Lewis gun is attached could be locked in any position around the ring. The W.B.II utilized the fin and rudder of the B.E.2c biplane, a type that was being manufactured by Beardmore.

In a new colour scheme, the W.B.II was photographed at Martlesham Heath.

Built as a private venture by William Beardmore & Co Ltd in 1917, the W.B.II two-seat fighter is shown at Martlesham Heath in December that year.

Built as a private venture by William Beardmore & Co Ltd in 1917, the W.B.II two-seat fighter is shown at Martlesham Heath in December that year.

Note the elevators are painted RNAS style in red/white/blue stripes, the same as the rudder stripes.

The W.B.II in its final guise with raised gun ring and modified engine cowling, exhaust stubs replacing the original stacks, and the shape of the under-slung oil tank has been improved. Probably at the Isle of Grain.

The W.B.II in its final form. The built-up rear cockpit and the new nose contour without the spinner are noteworthy. The Beardmore-Richards gun mounting is clearly visible.

In this photograph the W.B.II appears to have a standard Scarff ring mounting in the rear cockpit. Martlesham Heath, December 1917.

In this photograph the W.B.II appears to have a standard Scarff ring mounting in the rear cockpit. Martlesham Heath, December 1917.

Beard more W.B.II I Folding Pup

The Beardmore W.B.III provides an example of what not to do to improve a good design. The Sopwith Pups of the RNAS pioneered deck flying and were used on the turret platforms of capital ships as anti-Zeppelin weapons.

Flt Lt G.M. Bryer served in the RNAS and RAF on the aircraft carriers Furious and Argus. His recollections for the RAF Staff College of his service experiences are detailed and provide a hint as to what operating aircraft with the Fleet was like.

The carriage of fast climbing fighters in the Grand Fleet had the effect of making the Zeppelins keep higher, and to show themselves less often. This far had the aim of carrying fighters in ships had been attained, but to the pilots detailed to fly them, it seemed monotonous and unsatisfying to go to sea, perhaps five days a week, without sighting a target, or even flying the aeroplane, which took so much work to keep it in flying condition while perched on a tiny platform, exposed to wind, rain, salt spray, condensation, sometimes small-gun concussion and always the inborn hatred of the sailor for anything not of the sea.

The problem with the Sopwith Pup was that it took up a lot of space and while the Short and Fairey seaplanes had been designed from the start to have folding wings for hangar stowage, the Pup did not. It was decided that the Pup should be modified to have folding wings and the Beardmore Company was selected to produce this variant of the Pup.

Beardmore had been the first company to produce the Pup under licence and therefore was a logical choice for the task.

In October 1916, the decision was made to place an order with the Beardmore firm to convert a Sopwith 80-hp Fighter to fly off the deck of a ship, also to supply the water tight cases required.

Sopwith Pup No. 9950 was selected for the modification program. In order to fold the wings, the wing cellule had to be completely redesigned while retaining the basic Pup components. The centre section was reduced in width and small stub-wings were added against the fuselage for the lower wings. The ailerons were connected by struts. Stagger was eliminated and the wings were hinged at the main rear spar close up to the fuselage. Two sets of interplane struts were fitted to each set of mainplanes to preserve the truss when the wings were folded. The cabane struts of the Pup were replaced by four long struts, two on each side of the fuselage which were connected to the upper longeron by a short horizontal strut. While the fuselage looked the same as the Pup’s it was about a foot longer in order that the interplane struts were not interfered with by the tailplane when the wings were folded. A standard Pup tailplane was used.

In order to reduce the size of the folded machine the prototype was fitted with a folding undercarriage. The front members of the Vee were hinged and the rear members fitted with a quick device that the pilot could operate from his cockpit. This allowed the wheels to fold up into the fuselage leaving half the wheels exposed. To achieve this track was reduced and because of perceived handling difficulties with this narrow track, folding skids were fitted under the lower wing tips.

Armament was an upward firing Lewis gun on a tripod mounting in front of the cockpit. As rockets were still considered an anti-Zeppelin weapon, rocket-launching equipment was considered part of the type’s armament.

The machine was known as the S.B.3 for Sopwith-Beardmore acknowledging the origin of the type. The Beardmore designation of W.B.III was not used by the Admiralty. G.Tilghman-Richards, the head of Beardmore’s design department, acknowledged that it was a re-design of the Sopwith Pup and not a true Beardmore creation.

The prototype S.B.3F was delivered by rail to the Design Flight at Eastchurch on 2 February 1917, and was accepted on the 7th. It encountered a force landing on 10 March under the control of Flt Lt P. A. Johnston. Recorded under repair on the 12th, on 17 April it was being dismantled. It lost its engine to Sopwith Pup No. 9922 on 1 May, and was finally written off on 19 June 1917.

One hundred production machines were ordered from Beardmore (N6100-N6129 and N6680-N6749).

At the Admiralty Air Department’s Weekly Progress Committee of 26 June 1917, it was reported that HMS Furious required machines with dropping undercarriages whereas all the first 15 machines were at present to have the folding chassis. Capt A.V. Vyvyan said that Cdr Dunning had raised the question and it had been arranged for all Furious’s machines to have drooping undercarriages. In fact, Vyvyan stated that it appeared to him that no one wanted the folding undercarriage. In reply Cdr Longmore informed the Meeting that 15 of the first order and 20 of the second order were to have the folding chassis and they would still be of use in the cruisers such as Yarmouth, that had small stowage spaces and were unable to take machines with the standard type chassis. The name of the type was discussed and it was agreed that they be known as the Sopwith Beardmore or S.B. Type. They were designated with folding undercarriages, and S.B.3D with dropping undercarriages. It appears that most of the S.B.3F types were converted to the dropping undercarriage as official RNAS lists show only the S.B.3D in service.

On the S.B.3D the interplane struts at the end of the wings were discarded. The ailerons were connected by cables. The Lewis gun was mounted above the centre section and the cut-out was done away with. Air bags were run along the underside of the leading edge of the lower mainplanes where the lay almost flush under the wing, and, in the case of a forced alighting on the sea, could be inflated from the cockpit. Lt W.G. Moore made a test of this equipment when he ditched his Pup (a folder) that had a hydrovane and air bags in Sheerness Harbour.

At the Meeting of 3 July, Cdr Longmore reported how he had visited Cassandra, Furious and Beardmores at Glasgow and the Air Stations at East Fortune and South Shields. Cassandra's view was that because of the extra weight placed on their Sopwith Pups in the form of air bags, gas bottles, etc., it would be better for the whole of the order for the folding Pups to have the dropping chassis and to abandon the folding chassis altogether. This would mean that when the machine got off and dropped its chassis it would have a clear gain of about 50 lbs less weight and also less head resistance.

As noted above, Beardmore had been visited, and had agreed to provide all their order with dropping undercarriages. The first machine with folding chassis had been delivered to Cassandra and if possible, the second machine would be got out in time, i.e. by Friday of this week when “Cassandra" sails, and substituted for the first machine which would be taken back by Beardmores and altered. No. N6100 had been delivered to Cassandra on 3 December 1917. The second machine was allotted to Yarmouth and the allocations would have to be amended accordingly.

Despite the decision by the Air Department to call the machines the S.B. the next time it came up in the Minutes it was headed “Beardmore Folders” and were commonly known as Beardmore Folding Pups. The item reported that Cassandra’s machine, No. 6100, had not much performance. Preliminary trials with No. 6102 at Grain showed it was not the wing air bags that were causing the trouble. Further trials were to be carried out without the chassis and if this did not explain the trouble, the centre section would be looked to. Cdr Longmore stated that he thought the fault was with the centre-section and that Cdr Rutland agreed with him. He proposed that the centre section befilled in and a “Vindex” gun mounting fitted. A good gun mounting is required for these Folder Pups. To a suggestion that a new one should be developed, while it was agreed to, it would take some time to introduce and it was finally decided to press on with the trials of the 2 machines at Grain and await results as to performance. Nos. N6102 and N6103 were the two machines at Grain, both arriving in July 1917. Construction had been halted for a month as the ship carrying the Le Rhone engines had been sunk in the Channel. No. N6104 did not fly until 10 August 1917.

At the next Meeting Longmore reported on Nos. N6102 and N6103 at Grain. N6103 was officially allocated to Grain

on 20 June 1917, but the acceptance test flight took place on 10 July at Dalmuir by A. Dukinfield Jones. The following trials were being carried out at Grain. On one machine a Climb Test for ceiling without chassis and a speed test at 10,000 feet finishing with a landing in the water. Machine then to befitted with a 100 Mono Gnome with special carburettor. After which trials to be repeated.

On the other machine - accurate type trials with chassis on, wing air bags, etc., as supplied. The centre section filled in and gun fixed on after spar to obtain accurate figures.

Late August saw Longmore reporting that the first few of the Beardmore Folders had been turned out but it was not considered that they were entirely satisfactory. Modifications were suggested by the Admiralty Technical Department and even though this would mean a delay of three weeks as long as the demand for Pups can be met, the modifications should be gone on with.

At the next Meeting Longmore was able to give the results of testing of the Beardmore Folders at Grain.

With chassis on: 10.000 ft in 20 min 45 sec as against similar test before modification showing - 9,000 ft in 28 min and a speed of 78 mph at 10,000 ft against 76 mph at 9,000 ft.

Despite this improvement, Capt Vyvyan carried the news to the next Meeting that pilot's in seaplane carriers do not now want the Beardmore Folders. It was pointed out that this was due to the failure of the original machine. The modifications were now being incorporated and deliveries would start this week. Despite this, it was reported that the gun mounting had now been settled and was being fitted but that it would not be satisfactory owing to the very bad view.

More problems arose with a report of stating that the Class 1 modifications asked for by T.1N Section (Technical Section) affecting the ailerons would cause greater delay than was at first anticipated. The strength of these machines was found to be below requirements and delivery would therefore be delayed about one month.

Longmore submitted a minute in August 1917 wherein he noted that the present Sopwith Beardmore Folder has not a very good performance, and can only be regarded as makeshift until some better type appears. By January 1918, the USN noted that the S.B.3D Sopwith Beardmore with dropping chassis and carrying airbags, which is a modified Pup; not a satisfactory machine & is being superseded by the Sopwith 2F.1 Camel with detachable fuselage which has a much better performance.

Difficulties in construction, changes and the Admiralty wanting Beardmore to concentrate on airship building in June 1917, led to delays in the production of the S.B.III biplanes. Delays in engine allocation saw many delivered straight into store without engines.

Sir Austin Robertson recalled that at Killingholme there were also a large number of Beardmore WB.Ills, presumably in case the Fleet came into Immingham and wanted replacements in a hurry.

The S.B.III was not popular with pilots. The modifications had changed the Pup from a superlative pilot’s aeroplane to a mediocre one. Some S.B.III Folders did serve in the Fleet. On 21 October 1918,18 were with the Grand Fleet and 55 were in storage.

Flt Sub-Lt Stuart D. Culley joined the RNAS in Canada in 1917. After preliminary training and the seaplane course, it being necessary or all Fleet pilots to be qualified in these types of aircraft, he was sent in 1918 to undertake deck flying training in HMS Nairana. He was then ordered to join HMS Cassandra, a light cruiser of the then new “C” class, in the 6th Light Cruiser Squadron of the Grand Fleet.

The aircraft on this cruiser consisted of one folding wing Sopwith "Pup” fitted with a 80 H.P. Le Rhone engine. The aircraft was housed in a small steel hangar, barely large enough to accommodate it with its wings folded. No flying platform was available, but two troughs were fitted on the forecastle with a quick release gear. This gear comprised a trestle to hold the tail in flying position. On top of the trestle there being a groove to guide the tail skid. The pilot opened the engine full out and pulled a toggle in the cockpit which operated an ordinary bomb release anchored to the deck at one end and engaged with a cable attached to the aircraft. On release, the aircraft accelerated quickly and left the deck with a shorter run than a normal take-off.

The folding wing "Pup” was specially designed for anti-Zeppelin work and every consideration had been given to saving weight. The undercarriage struts and axle were made of duralumin while the fabric on the planes and fuselage was coated not more than two coats of clear dope.

The armament consisted of one Lewis gun mounted on the top centre section and fitted with one 97 round drum of ammunition known as “ZPYT” being a mixture of Brock and Pomeroy explosive bullets together with a certain amount of tracer and ordinary ammunition.

I was the only pilot and had with me two mechanics, one fitter and the other a rigger.

During the period I was in H.M.S. Cassandra I found it difficult to maintain flying practice even though the Captain was quite sympathetic. Only once could I obtain the permission of the Admiral to fly my aircraft off the deck, and go to Donnibristle for practice flying involving a day’s absence which was not encouraged as the Fleet was normally at two hours notice. I therefore became less qualified as a pilot and more qualified as a Naval Officer, being required to keep my “day on” as Officer of the Watch, whilst the ship was in harbour, and the “morning” watch, when at sea, besides acting as an assistant to the Navigating Officer at other times.

As noted in Chapter 2, Culley was to earn fame when he brought down the Zeppelin L53 while flying a Beardmore-built Sopwith 2F.1 Camel from a towed lighter.

Geoffrey Moore served on HMS Furious and wrote that the Sopwith Pup was a very controllable and pleasant to fly fighter. Some we had in Furious were modified by Beardmore’s to fold for passing down a hatch and stowing between decks. This folding rather spoiled their performance and handiness; to make them fold conveniently they reduced some of the wing stagger, consequently they did not handle as nicely as the standard series. I used to give little exhibitions of aerobatics for the entertainment of the fleet but was never happy when doing this in a folder on a account of some lack of response in the controls, and I was always wondering whether, if subjected to exceptional strain, they would 'fold’ in the air.

Flt Lt G.M. Bryer noted that Prudence had produced a small aeroplane, with air-bags in the fuselage and a detachable undercarriage, for use in ships. It was based on the Sopwith “Pup” design, with an 80 H.P. Le Rhone engine and built by Beardmores. It was slow in speed and climb. It carried only one gun, on the top plane, for explosive ammunition. This gave way to a more effective weapon the Sopwith 2F.1 Ships Camel. Its performance was little less than that of the standard “Camel”, but was far ahead of the Beardmore “Ship Scout” or the “Pup”.

A few Beardmore W.B.III fighters were sent to Japan for their Navy’s interest in setting up an air service. The type soon disappeared after the Armistice.

Serial Allocation Beardmore WB.III

Serial Contract No. Notes

9950 C.P.117318/16 Last Sopwith Pup of this contact for 50 Pups by Sir William Beardmore & Co Ltd. Converted to prototype S.B.3F.

N6100-N6129 A.S.775/17 & A.S.14577 Majority converted to S.B.3D type.

N6680-N6749 A.S.77517 & A.S.12856 S.B.3D. 42 were cancelled on 5 February 1918, but reinstalled. Most straight to store.

Beardmore W.B.III Specifications

Source 1 2 3 4 (2) 4 (3) 5 (4)

Span 25 ft 25 ft 1 in 25 ft - - 25 ft 3 in

Span folded - - - - - 10 ft 6-in

Length 20 ft 2 1/4 in 19 ft 4 in 20 ft 2.5 in - - -

Height 8 ft 1 1/4 in 8 ft 8 in 8 ft 1.25 in - - 8 ft 6 in

Height S.B.3F - - - - - 6 ft

Gap - - 4 ft 9 in - - 4 ft 5 in

Chord - - 5 ft 1.5 in - - 5 ft 1 1/2 in

Incidence - - - - - 1° 30’

Span tailplane - - 10 ft 1 in - 10 ft 1 in

Airscrew Dia - - 8 ft 6 in - - -

Wing area, ft2 243 - 243 218.5 236 236

Aileron area, ft2 - - 23 - - 22

Tail (total), ft2 - - 34.5 - - 23

Elevator area, ft2 - - 11.5 - - 11.8

Rudder area, ft2 - - 4.5 - - 4.2

Fin area, ft2 - - 3.5 - - 3.3

Weights in lbs

Empty - - 880 828 849 -

Fuel & Oil - - - 181 165 -

Military load - - - 49 36 -

Crew - - - 180 180 -

Disposable load (1) - - 300 - - -

Total - - 1,290 1,238 1,230 -

Fuel in gall - - 18 - - -

Speed

at GL 103 mph - 103 mph - - -

at 2,000 ft - - - - 78.5 kts -

at 6,500 ft 98 mph - - - 74 kts -

at 10,000 ft 91 mph - 88 mph 78 kts 68.5 kts -

Landing - - 40 mph - - -

Service Ceiling 12,400 ft - - - - -

Endurance, hrs 2 3/4 - 2.75 3 2 3/4 -

Engines 80-hp Le Rhone or 80-hp Clerget - 80-hp Le Rhone or 80-hp Clerget 80-hp Le Rhone 80-hp Le Rhone -

Notes:

(1) Excluding fuel.

(2) Beardmore Folder. Date Trial Report 08 Feb 1917.

(3) Beardmore Folder (Air Bag). Date Trial Report 03 Sept 1917.

(4) Probably relate to prototype No. 9950.

Source:

1. J.M. Bruce Data.

2. Types of British Seaplanes, Flying Boats and Ship’s Aeroplanes.TNA. AIR10/96.

3. Jane’s All the World’s Aircraft 1919. Arco Publishing USA 1990.

4. Tables of Performances of Seaplanes & Flying Boats. 31 October 1917. TNA AIR1/708/27/11/03.

5. The Sopwith Pup, Bruce, J.M., Page, G & Sturtivant, R. Air Britain, UK. 2002.

The Beardmore W.B.III provides an example of what not to do to improve a good design. The Sopwith Pups of the RNAS pioneered deck flying and were used on the turret platforms of capital ships as anti-Zeppelin weapons.

Flt Lt G.M. Bryer served in the RNAS and RAF on the aircraft carriers Furious and Argus. His recollections for the RAF Staff College of his service experiences are detailed and provide a hint as to what operating aircraft with the Fleet was like.

The carriage of fast climbing fighters in the Grand Fleet had the effect of making the Zeppelins keep higher, and to show themselves less often. This far had the aim of carrying fighters in ships had been attained, but to the pilots detailed to fly them, it seemed monotonous and unsatisfying to go to sea, perhaps five days a week, without sighting a target, or even flying the aeroplane, which took so much work to keep it in flying condition while perched on a tiny platform, exposed to wind, rain, salt spray, condensation, sometimes small-gun concussion and always the inborn hatred of the sailor for anything not of the sea.

The problem with the Sopwith Pup was that it took up a lot of space and while the Short and Fairey seaplanes had been designed from the start to have folding wings for hangar stowage, the Pup did not. It was decided that the Pup should be modified to have folding wings and the Beardmore Company was selected to produce this variant of the Pup.

Beardmore had been the first company to produce the Pup under licence and therefore was a logical choice for the task.

In October 1916, the decision was made to place an order with the Beardmore firm to convert a Sopwith 80-hp Fighter to fly off the deck of a ship, also to supply the water tight cases required.

Sopwith Pup No. 9950 was selected for the modification program. In order to fold the wings, the wing cellule had to be completely redesigned while retaining the basic Pup components. The centre section was reduced in width and small stub-wings were added against the fuselage for the lower wings. The ailerons were connected by struts. Stagger was eliminated and the wings were hinged at the main rear spar close up to the fuselage. Two sets of interplane struts were fitted to each set of mainplanes to preserve the truss when the wings were folded. The cabane struts of the Pup were replaced by four long struts, two on each side of the fuselage which were connected to the upper longeron by a short horizontal strut. While the fuselage looked the same as the Pup’s it was about a foot longer in order that the interplane struts were not interfered with by the tailplane when the wings were folded. A standard Pup tailplane was used.

In order to reduce the size of the folded machine the prototype was fitted with a folding undercarriage. The front members of the Vee were hinged and the rear members fitted with a quick device that the pilot could operate from his cockpit. This allowed the wheels to fold up into the fuselage leaving half the wheels exposed. To achieve this track was reduced and because of perceived handling difficulties with this narrow track, folding skids were fitted under the lower wing tips.

Armament was an upward firing Lewis gun on a tripod mounting in front of the cockpit. As rockets were still considered an anti-Zeppelin weapon, rocket-launching equipment was considered part of the type’s armament.

The machine was known as the S.B.3 for Sopwith-Beardmore acknowledging the origin of the type. The Beardmore designation of W.B.III was not used by the Admiralty. G.Tilghman-Richards, the head of Beardmore’s design department, acknowledged that it was a re-design of the Sopwith Pup and not a true Beardmore creation.

The prototype S.B.3F was delivered by rail to the Design Flight at Eastchurch on 2 February 1917, and was accepted on the 7th. It encountered a force landing on 10 March under the control of Flt Lt P. A. Johnston. Recorded under repair on the 12th, on 17 April it was being dismantled. It lost its engine to Sopwith Pup No. 9922 on 1 May, and was finally written off on 19 June 1917.

One hundred production machines were ordered from Beardmore (N6100-N6129 and N6680-N6749).

At the Admiralty Air Department’s Weekly Progress Committee of 26 June 1917, it was reported that HMS Furious required machines with dropping undercarriages whereas all the first 15 machines were at present to have the folding chassis. Capt A.V. Vyvyan said that Cdr Dunning had raised the question and it had been arranged for all Furious’s machines to have drooping undercarriages. In fact, Vyvyan stated that it appeared to him that no one wanted the folding undercarriage. In reply Cdr Longmore informed the Meeting that 15 of the first order and 20 of the second order were to have the folding chassis and they would still be of use in the cruisers such as Yarmouth, that had small stowage spaces and were unable to take machines with the standard type chassis. The name of the type was discussed and it was agreed that they be known as the Sopwith Beardmore or S.B. Type. They were designated with folding undercarriages, and S.B.3D with dropping undercarriages. It appears that most of the S.B.3F types were converted to the dropping undercarriage as official RNAS lists show only the S.B.3D in service.

On the S.B.3D the interplane struts at the end of the wings were discarded. The ailerons were connected by cables. The Lewis gun was mounted above the centre section and the cut-out was done away with. Air bags were run along the underside of the leading edge of the lower mainplanes where the lay almost flush under the wing, and, in the case of a forced alighting on the sea, could be inflated from the cockpit. Lt W.G. Moore made a test of this equipment when he ditched his Pup (a folder) that had a hydrovane and air bags in Sheerness Harbour.

At the Meeting of 3 July, Cdr Longmore reported how he had visited Cassandra, Furious and Beardmores at Glasgow and the Air Stations at East Fortune and South Shields. Cassandra's view was that because of the extra weight placed on their Sopwith Pups in the form of air bags, gas bottles, etc., it would be better for the whole of the order for the folding Pups to have the dropping chassis and to abandon the folding chassis altogether. This would mean that when the machine got off and dropped its chassis it would have a clear gain of about 50 lbs less weight and also less head resistance.

As noted above, Beardmore had been visited, and had agreed to provide all their order with dropping undercarriages. The first machine with folding chassis had been delivered to Cassandra and if possible, the second machine would be got out in time, i.e. by Friday of this week when “Cassandra" sails, and substituted for the first machine which would be taken back by Beardmores and altered. No. N6100 had been delivered to Cassandra on 3 December 1917. The second machine was allotted to Yarmouth and the allocations would have to be amended accordingly.

Despite the decision by the Air Department to call the machines the S.B. the next time it came up in the Minutes it was headed “Beardmore Folders” and were commonly known as Beardmore Folding Pups. The item reported that Cassandra’s machine, No. 6100, had not much performance. Preliminary trials with No. 6102 at Grain showed it was not the wing air bags that were causing the trouble. Further trials were to be carried out without the chassis and if this did not explain the trouble, the centre section would be looked to. Cdr Longmore stated that he thought the fault was with the centre-section and that Cdr Rutland agreed with him. He proposed that the centre section befilled in and a “Vindex” gun mounting fitted. A good gun mounting is required for these Folder Pups. To a suggestion that a new one should be developed, while it was agreed to, it would take some time to introduce and it was finally decided to press on with the trials of the 2 machines at Grain and await results as to performance. Nos. N6102 and N6103 were the two machines at Grain, both arriving in July 1917. Construction had been halted for a month as the ship carrying the Le Rhone engines had been sunk in the Channel. No. N6104 did not fly until 10 August 1917.

At the next Meeting Longmore reported on Nos. N6102 and N6103 at Grain. N6103 was officially allocated to Grain

on 20 June 1917, but the acceptance test flight took place on 10 July at Dalmuir by A. Dukinfield Jones. The following trials were being carried out at Grain. On one machine a Climb Test for ceiling without chassis and a speed test at 10,000 feet finishing with a landing in the water. Machine then to befitted with a 100 Mono Gnome with special carburettor. After which trials to be repeated.

On the other machine - accurate type trials with chassis on, wing air bags, etc., as supplied. The centre section filled in and gun fixed on after spar to obtain accurate figures.

Late August saw Longmore reporting that the first few of the Beardmore Folders had been turned out but it was not considered that they were entirely satisfactory. Modifications were suggested by the Admiralty Technical Department and even though this would mean a delay of three weeks as long as the demand for Pups can be met, the modifications should be gone on with.

At the next Meeting Longmore was able to give the results of testing of the Beardmore Folders at Grain.

With chassis on: 10.000 ft in 20 min 45 sec as against similar test before modification showing - 9,000 ft in 28 min and a speed of 78 mph at 10,000 ft against 76 mph at 9,000 ft.

Despite this improvement, Capt Vyvyan carried the news to the next Meeting that pilot's in seaplane carriers do not now want the Beardmore Folders. It was pointed out that this was due to the failure of the original machine. The modifications were now being incorporated and deliveries would start this week. Despite this, it was reported that the gun mounting had now been settled and was being fitted but that it would not be satisfactory owing to the very bad view.

More problems arose with a report of stating that the Class 1 modifications asked for by T.1N Section (Technical Section) affecting the ailerons would cause greater delay than was at first anticipated. The strength of these machines was found to be below requirements and delivery would therefore be delayed about one month.

Longmore submitted a minute in August 1917 wherein he noted that the present Sopwith Beardmore Folder has not a very good performance, and can only be regarded as makeshift until some better type appears. By January 1918, the USN noted that the S.B.3D Sopwith Beardmore with dropping chassis and carrying airbags, which is a modified Pup; not a satisfactory machine & is being superseded by the Sopwith 2F.1 Camel with detachable fuselage which has a much better performance.

Difficulties in construction, changes and the Admiralty wanting Beardmore to concentrate on airship building in June 1917, led to delays in the production of the S.B.III biplanes. Delays in engine allocation saw many delivered straight into store without engines.

Sir Austin Robertson recalled that at Killingholme there were also a large number of Beardmore WB.Ills, presumably in case the Fleet came into Immingham and wanted replacements in a hurry.

The S.B.III was not popular with pilots. The modifications had changed the Pup from a superlative pilot’s aeroplane to a mediocre one. Some S.B.III Folders did serve in the Fleet. On 21 October 1918,18 were with the Grand Fleet and 55 were in storage.

Flt Sub-Lt Stuart D. Culley joined the RNAS in Canada in 1917. After preliminary training and the seaplane course, it being necessary or all Fleet pilots to be qualified in these types of aircraft, he was sent in 1918 to undertake deck flying training in HMS Nairana. He was then ordered to join HMS Cassandra, a light cruiser of the then new “C” class, in the 6th Light Cruiser Squadron of the Grand Fleet.

The aircraft on this cruiser consisted of one folding wing Sopwith "Pup” fitted with a 80 H.P. Le Rhone engine. The aircraft was housed in a small steel hangar, barely large enough to accommodate it with its wings folded. No flying platform was available, but two troughs were fitted on the forecastle with a quick release gear. This gear comprised a trestle to hold the tail in flying position. On top of the trestle there being a groove to guide the tail skid. The pilot opened the engine full out and pulled a toggle in the cockpit which operated an ordinary bomb release anchored to the deck at one end and engaged with a cable attached to the aircraft. On release, the aircraft accelerated quickly and left the deck with a shorter run than a normal take-off.

The folding wing "Pup” was specially designed for anti-Zeppelin work and every consideration had been given to saving weight. The undercarriage struts and axle were made of duralumin while the fabric on the planes and fuselage was coated not more than two coats of clear dope.

The armament consisted of one Lewis gun mounted on the top centre section and fitted with one 97 round drum of ammunition known as “ZPYT” being a mixture of Brock and Pomeroy explosive bullets together with a certain amount of tracer and ordinary ammunition.

I was the only pilot and had with me two mechanics, one fitter and the other a rigger.

During the period I was in H.M.S. Cassandra I found it difficult to maintain flying practice even though the Captain was quite sympathetic. Only once could I obtain the permission of the Admiral to fly my aircraft off the deck, and go to Donnibristle for practice flying involving a day’s absence which was not encouraged as the Fleet was normally at two hours notice. I therefore became less qualified as a pilot and more qualified as a Naval Officer, being required to keep my “day on” as Officer of the Watch, whilst the ship was in harbour, and the “morning” watch, when at sea, besides acting as an assistant to the Navigating Officer at other times.

As noted in Chapter 2, Culley was to earn fame when he brought down the Zeppelin L53 while flying a Beardmore-built Sopwith 2F.1 Camel from a towed lighter.

Geoffrey Moore served on HMS Furious and wrote that the Sopwith Pup was a very controllable and pleasant to fly fighter. Some we had in Furious were modified by Beardmore’s to fold for passing down a hatch and stowing between decks. This folding rather spoiled their performance and handiness; to make them fold conveniently they reduced some of the wing stagger, consequently they did not handle as nicely as the standard series. I used to give little exhibitions of aerobatics for the entertainment of the fleet but was never happy when doing this in a folder on a account of some lack of response in the controls, and I was always wondering whether, if subjected to exceptional strain, they would 'fold’ in the air.

Flt Lt G.M. Bryer noted that Prudence had produced a small aeroplane, with air-bags in the fuselage and a detachable undercarriage, for use in ships. It was based on the Sopwith “Pup” design, with an 80 H.P. Le Rhone engine and built by Beardmores. It was slow in speed and climb. It carried only one gun, on the top plane, for explosive ammunition. This gave way to a more effective weapon the Sopwith 2F.1 Ships Camel. Its performance was little less than that of the standard “Camel”, but was far ahead of the Beardmore “Ship Scout” or the “Pup”.

A few Beardmore W.B.III fighters were sent to Japan for their Navy’s interest in setting up an air service. The type soon disappeared after the Armistice.

Serial Allocation Beardmore WB.III

Serial Contract No. Notes

9950 C.P.117318/16 Last Sopwith Pup of this contact for 50 Pups by Sir William Beardmore & Co Ltd. Converted to prototype S.B.3F.

N6100-N6129 A.S.775/17 & A.S.14577 Majority converted to S.B.3D type.

N6680-N6749 A.S.77517 & A.S.12856 S.B.3D. 42 were cancelled on 5 February 1918, but reinstalled. Most straight to store.

Beardmore W.B.III Specifications

Source 1 2 3 4 (2) 4 (3) 5 (4)

Span 25 ft 25 ft 1 in 25 ft - - 25 ft 3 in

Span folded - - - - - 10 ft 6-in

Length 20 ft 2 1/4 in 19 ft 4 in 20 ft 2.5 in - - -

Height 8 ft 1 1/4 in 8 ft 8 in 8 ft 1.25 in - - 8 ft 6 in

Height S.B.3F - - - - - 6 ft

Gap - - 4 ft 9 in - - 4 ft 5 in

Chord - - 5 ft 1.5 in - - 5 ft 1 1/2 in

Incidence - - - - - 1° 30’

Span tailplane - - 10 ft 1 in - 10 ft 1 in

Airscrew Dia - - 8 ft 6 in - - -

Wing area, ft2 243 - 243 218.5 236 236

Aileron area, ft2 - - 23 - - 22

Tail (total), ft2 - - 34.5 - - 23

Elevator area, ft2 - - 11.5 - - 11.8

Rudder area, ft2 - - 4.5 - - 4.2

Fin area, ft2 - - 3.5 - - 3.3

Weights in lbs

Empty - - 880 828 849 -

Fuel & Oil - - - 181 165 -

Military load - - - 49 36 -

Crew - - - 180 180 -

Disposable load (1) - - 300 - - -

Total - - 1,290 1,238 1,230 -

Fuel in gall - - 18 - - -

Speed

at GL 103 mph - 103 mph - - -

at 2,000 ft - - - - 78.5 kts -

at 6,500 ft 98 mph - - - 74 kts -

at 10,000 ft 91 mph - 88 mph 78 kts 68.5 kts -

Landing - - 40 mph - - -

Service Ceiling 12,400 ft - - - - -

Endurance, hrs 2 3/4 - 2.75 3 2 3/4 -

Engines 80-hp Le Rhone or 80-hp Clerget - 80-hp Le Rhone or 80-hp Clerget 80-hp Le Rhone 80-hp Le Rhone -

Notes:

(1) Excluding fuel.

(2) Beardmore Folder. Date Trial Report 08 Feb 1917.

(3) Beardmore Folder (Air Bag). Date Trial Report 03 Sept 1917.

(4) Probably relate to prototype No. 9950.

Source:

1. J.M. Bruce Data.

2. Types of British Seaplanes, Flying Boats and Ship’s Aeroplanes.TNA. AIR10/96.

3. Jane’s All the World’s Aircraft 1919. Arco Publishing USA 1990.

4. Tables of Performances of Seaplanes & Flying Boats. 31 October 1917. TNA AIR1/708/27/11/03.

5. The Sopwith Pup, Bruce, J.M., Page, G & Sturtivant, R. Air Britain, UK. 2002.

The second production Beardmore W.B.III with jettisonable undercarriage, as adopted for the subsequent S.B.3D version for naval use.

No. N6101 shows the centre-section cut and mount for the Lewis gun and the double interplane struts at the sub-wing root next to the fuselage. The logo on the fin is the Beardmore designation 'W.B.III.' Points to note include the tricoloured elevators and the white outer ring to the wing cockades on a clear doped wing; the poor streamlining of the fuselage cross section to the engine cowling; and the large folding wingtip skids; the strut connecting the ailerons. In November 1917, the axle of the S.B.3 was being strengthened and it is proposed that strengthened axles be sent to Rosyth to replace those presently fitted to machines. The Lewis gun tray rack is also being modified to clear the pilot's knees.

Beardmore S.B.3 No. N6102 on the Isle of Grain, 10 October 1917. N6102 was delivered to Grain for erection on 24 July 1917. It underwent testing by Sqn Cdr Harry R Busteed. Note the single interplane struts next to the fuselage and the cable connecting the ailerons.

Beardmore S.B.3 No. N6102 on the Isle of Grain, 10 October 1917. N6102 was delivered to Grain for erection on 24 July 1917. It underwent testing by Sqn Cdr Harry R Busteed. Note the single interplane struts next to the fuselage and the cable connecting the ailerons.

Beardmore S.B.3D No. N6708 has the modified wing that allowed for an over-wing Lewis gun mount. Note the steel tube undercarriage struts, ailerons connected by a cable and the lack of the folding wing tip skids. The long pitot would be for testing purposes. These photographs of N6708 were used to illustrate the type in the recognition manual Types of British Seaplanes, Flying Boats and Ships Aeroplanes.

Beardmore N6708 with the wings folded. Delivered to Grain on 13 December 1917, this SB.IIID was with HMS Nairana by the W/E 13 April 1918. It appears to have served with Nairana when not ashore being finally deleted when at Rosyth in late 1918.

A standard late production Beardmore W.B.III (S.B.3D). Obvious differences between this and the Sopwith Pup include the absence of wing stagger, the extra interplane struts close to the fuselage adjacent to the wing-fold line, the lengthened fuselage aft of the cockpit and the lengthened tailskid to allow ground clearance with the wings folded.

Beardmore N6708 taking flight. The modifications lost the Sopwith Pup's flying characteristics and it was not popular with pilots.

This photograph is thought to be some sort of trial of arrestor gear. Note the ropes leading to the landing gear of this S.B.3D. The man knelling at the rear has a handling bar attached to the rear fuselage.

Beardmore S.B.3D fighters taking off from HMS Nairana.The machines apparently ran down the ramp and dropped onto the flight deck - note the splay of the wheels - and then, hopefully, attained flight speed before they left the deck.

S.B.3D fighter take-off from HMS Nairana in the Firth of Forth. It appears that one of these machines were engaged on operations.

A Beardmore W.B.III leaves the steep forward launching platform of HMS Pegasus (HMS Nairana ???) in 1918.

Transporting an RAF S.B.III. Note the jury strut inserted between the wings when folded. This replaced the double struts used on a few of the very early S.B.III scouts.

Delivered to Killingholme, probably into store, N6748 was at No. 6 AAP Renfrew where this photograph was most probably taken. This machine had an 80-hp Le Rhone but is shown without an airscrew.

N6748 in the Beardmore works. Note the fuselage of one of the two Beardmore W.B.V ship aeroplane to the right background. N6748 was the second last machine from the batch N6680 to N6749. It was delivered to Killingholme Reserve in the W/E 23 February 1918, and probably was never flown. There appears to be no engine mounted when photographed. There was a lack of engines for the S.B.3D and many were delivered to store engineless.

N6748 in the Beardmore works. Note the fuselage of one of the two Beardmore W.B.V ship aeroplane to the right background. N6748 was the second last machine from the batch N6680 to N6749. It was delivered to Killingholme Reserve in the W/E 23 February 1918, and probably was never flown. There appears to be no engine mounted when photographed. There was a lack of engines for the S.B.3D and many were delivered to store engineless.

Прототип SB3 в положении для хранения в ангаре авианосца.

No. 9950 complete showing the undercarriage folded and the machine completely folded. This machine had an adjustable tailplane but the production machines did not. Note the narrow track of the folding undercarriage that required folding wingtip skids under the lower wing. A heightened tailskid was necessary to provide clearance for the wings in the folded position. Note the Lewis gun on its tripod mount firing through the upper wing centre section cut out.