Книги

Putnam

G.Haddow, P.Grosz

The German Giants

150

G.Haddow, P.Grosz - The German Giants /Putnam/

The Adlershof Projects

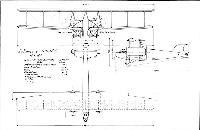

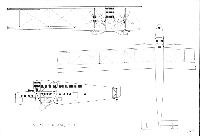

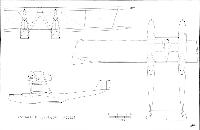

The following ten project drawings of R-planes were discovered among a pile of Zeppelin material that had found its way to the Air Museum at Wright Field. Even by today's standards, the size of some of the projected aircraft is immense, these drawings, more than anything else, reflect the thinking of German aeronautical engineers at the time. Unfortunately no information has been found to throw further light on these extremely interesting drawings. Six of the aircraft depicted follow the same twin fuselage configuration, differing in size and horsepower, and these show a strong resemblance to projected designs published by Junkers in the early 1920s. But the only concrete fact, apart from their existence, is that they originated from Adlershof.

The following ten project drawings of R-planes were discovered among a pile of Zeppelin material that had found its way to the Air Museum at Wright Field. Even by today's standards, the size of some of the projected aircraft is immense, these drawings, more than anything else, reflect the thinking of German aeronautical engineers at the time. Unfortunately no information has been found to throw further light on these extremely interesting drawings. Six of the aircraft depicted follow the same twin fuselage configuration, differing in size and horsepower, and these show a strong resemblance to projected designs published by Junkers in the early 1920s. But the only concrete fact, apart from their existence, is that they originated from Adlershof.

Adlershof R-plane project. 4/500 h.p. Benz. Span 48-4 m., length 26 m. 7 mg. This drawing shows a striking similarity to that of the Neuber project.

Adlershof R-plane project, dated August 1918. 12/500 h.p. engines. Span 114 m. length 48 m. This machine differs from that above in having four tractor and two pusher propellers.

Adlershof R-plane project. 16/500 h.p. engines. Span 130 m. A twenty-four man crew was planned for this aircraft. Armament comprised 16 machine-guns.

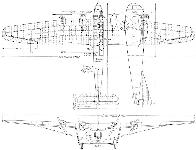

AEG R.I

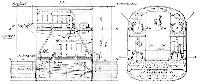

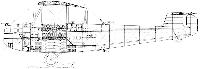

By virtue of the experience gained building twin-engined bombers, the Allgemeine Elektrizitats Gesellschaft (AEG) was included in the ambitious R-plane programme of 1916 along with SSW, Schutte-Lanz, Albatros, Aviatik and others. At the time, two giant bombers were ordered, designated R.I 21/16 and 22/16 and followed by an order for an additional six R.I machines numbered R.59 to R.64. Only one aircraft, the R.21, was flown before the end of hostilities. The R.I was born of much engineering skill and technical know-how as represented by AEG's staff of experienced engineers. Oberleutnant Bruckmann, former test pilot of the DFW R.I, was in charge of the venture established by AEG on 1 January 1917. Ing. Sander, formerly with DFW and SSW, was chief engineer, and his assistants were Dipl.-Ing. Werner Zorn, who also had been with DFW, and consultant Prof. Oesterlein of the Technische Hochschule, Brunswick. Design of the R.21 began in a rented eight-room flat in Berlin. An assembly shed was erected next to the Rumpler factory in Johannisthal. In the autumn of 1917 the design bureau moved there to supervise the construction of the R.21.

The R.I's long embryonic period from early 1917 until its first flight on 14 June 1918 reflected careful design, attention to detail and many hours of extensive bench tests. No effort was spared to incorporate lessons learned from the earlier giants, and many improvements and innovations were tried. Particularly noteworthy were the electrically-operated tailplane trim controls, the all-steel fuselage and the mixed steel and duraluminium wings. One of the most obstinate problems, which, perhaps, was never really solved, was engine misalignment and transmission vibration in centrally-powered aircraft. To mitigate this effect the R.I was literally built around a massive reinforced engine mount which supported fuselage, wings, landing gear and engines.

The four 260 h.p. Mercedes D.IVa engines were each linked to the drive system through a combination leather cone and dog clutch, while a fifth clutch connected each bank of engines. The airscrews were driven by two heavy transmission shafts running from a central gear-box to the propeller gear-box mounted between the wings. Articulated, sliding and universal joints were fitted to all connections to compensate for play and misalignment.

All four engines were started with a single Bosch inertia starter by first starting one engine and then "clutch-starting" the remainder. The exhaust gases were led into two large manifolds that were mounted in an indentation running along each side of the engine-room, permitting the exhaust system to operate in the airstream. Originally each engine had its own radiator bolted to the fuselage side, but later these were replaced by two large radiators composed of four separate units mounted on the centre-section struts. For a time, the AEG R.I was driven by four-bladed propellers, but these were soon replaced by two-bladed ones.

Cable-braced steel tubing was used exclusively on the frame-work of the fuselage. It was covered from the nose to the rear of the engine-room with plywood, the remainder was fabric-covered. The layout was typical of central-powered R-planes, with the exception that the pilots' cabin was situated aft of engines and wings. From this position it was considered easier for the pilot to judge his height during the critical touch-down phase, but this configuration, although tried in other R-planes, did not find favour with the crews.

The observer's cabin in the nose could be reached from the ground by a retractable ladder or through the engine-room directly aft. The cabin was fitted with glass windows to allow unobstructed vision to all sides. A spacious machine-gun post capable of holding two men was directly above the observer's cabin. The pilots' position was reached by stepping aft from the observer's cabin through a sliding door, passing through the engine-room (which was situated directly above the landing gear) between the engines on a small catwalk, and then climbing a small ladder to the cockpit. The cockpit seated two pilots and was fully-equipped with standard instruments, dual controls and the like. An engine telegraph similar in operation to those aboard ship, consisting of repeating pointers, provided communication between pilots and engine crew. The wireless cabin was located a few feet behind the cockpit, beneath the dorsal machine-gun post. The large windows on each side of the cabin indicated that beam machine-guns may have been considered. A ventral gun position was located in the floor.

The first R.I version had a curious semi-enclosed cabin which was later modified to a simple open cockpit for better visibility, and the enclosed dorsal gun position was replaced by a standard open gun ring. After modifying the cockpit, the fuselage had its greatest dimensions at this point, a depth of approximately 10 feet and a width of 6 feet.

The wing structure consisted of two chrome-nickel steel tube spars supporting duraluminium wing ribs, cable-braced throughout. Later AEG projects were to use rectangular aluminium girder spars designed and fabricated by Zeppelin-Werke, Lindau (Dornier), pioneers in this method of construction. The three-bay biplane wing structure was of equal span and chord. A curious feature was that the angle of incidence was washed-out towards the tips, giving the wings an unusual twisted appearance. This practice was fairly common on German aircraft of the period and was supposed to improve lateral control.

The controls of the R.I were unconventional, and it is a pity that only scant information is available. The elevator, for instance, was a forerunner of the all-flying tail of supersonic jets today. It was mounted some 5 feet over the tailplane, which itself could be electrically trimmed plus or minus several degrees. Two rudders were mounted between the elevator and tail plane out in the slipstream. Originally the gap between the two horizontal surfaces had been smaller, but after initial flight tests it was modified to improve control by adding more area to fin and rudders. The ailerons, rather than forming an integral part of the wing, were hinged to the outer two rear wing struts at a position midway between the wings. Like the high-set slab elevator, the aileron position was an innovation to avoid loss of control at critical angles of attack, particularly while landing.

The main landing wheels consisted of two wide-spoked hubs, each fitted with three tyres. Attached to each end of the main axle by a ball joint was an auxiliary landing gear, a kind of safety device that came into action only during a hard landing or sudden lurch that might throw the aircraft to one side.

The engine were ground tested on 23 and 30 May 1918. One engine with a broken connecting rod had to be replaced. On it first flight on 14 June 1918 the R.21, carrying a useful load of 1190 kg., flew for 27 minutes and climbed to 100 metres in a little under 10 minutes. The maiden flight was not without difficulties. With the engines throttled back the aircraft proved to be extremely tail heavy, even with full-down elevator the nose continued to rise. Only by shifting all available weight to the front was a safe landing made possible. After this initial flight the R.21 was modified as already described. It was hoped to have the work completed by 15 July 1918.

After a number of test flights it was determined that the propeller were not suitable. Additional sections were glued on at the propeller factory. Dipl.-Ing. Zorn warned Bruckmann that at least ten days would be required for the glue to set, but after only four days on 3 September 1918 Bruckmann ordered the propellers fitted to complete the urgent test programme. About an hour after the start a propeller flew apart, causing the cardan shaft to tear loose and shatter the centre-section structure. The R.21 broke up in the air over Rudow, killing seven men, including Bruckmann, Lt. Otto Reichardt (formerly commander of the R.13) and Lt. Dr. Oskar Wittenstein, both pre-war pilots attached to the Kommando-Riesenflugzeug-Abteilungen. Max Fiedler, who was flying escort in a Rumpler C.I, remembers the accident as follows:

I recall being slightly over the R.21 at about 6000 feet, when Bruckmann celebrating the event waved a cognac bottle as the R.21 swung into a left and then a right bank. There was a flutter and suddenly the wings folded back. It was a frightful sight.

Work on the partially completed R.22 was immediately halted until the cause of the catastrophe could be determined and fully evaluated by Idflieg.

An Idflieg document of 15 March 1918 listed these projected delivery dates for the AEG R.I aircraft: R.21 in April, R.22 and R.59 in June, R.60 in July, R.61 in September, R.62 in October 1918. The delivery dates of the R.63 and R.64 were not listed. In spite of this optimistic schedule, only the R.21 as completed. The R.22 (which was subject of discussions between Idflieg and AEG concerning an increase in wing area as late as 5 November 1918) was partially completed at the end of the war, but not enough to prevent it from being scrapped. Only portions of the R.59 to 64 series were begun, and after the war three R.I fuselage nose sections were photographed in the AEG scrap yard.

Like SSW, AEG possessed enough resources to weather the post-war period, and it is today among the largest of German electrical concerns.

Colour Scheme and Markings

The overall finish was the standard printed camouflage pattern. The design consisted of a repeated pattern of irregular polygons of five or six dull colours, such as grey, mauve, sage green, purple, blue and black. The actual colours and patterns varied with the sources of supply of the different aircraft manufacturers, but were all required to conform to a general standard set by Idflieg. After covering, the fabric was clear doped so that the printed pattern showed through. Latin crosses were painted on the wingtips, fuselage sides and rudders. The first version of the R.I had the early 1918 form of the Latin cross with short, broad arms, but the usual wide white outline was reduced to a thin white band. The final version of the R.I carried the standard Latin cross in use at the end of the war.

SPECIFICATIONS

Type: AEG R.I

Manufacturer: Allgemeine Elektrizitats Gesellschaft, Henningsdorf near Berlin

Engines: Four 260 h.p. Mercedes D.IVa engines

Propeller Revolutions: 750 r.p.m.

Dimensions: Span, 36 m. (118 ft. 1 1/2 in)

Chord, 3•8 m. (12 ft. 6 in.)

Gap, 4•5 to 4 m. (14 ft. 9 in. to 13 ft. 1 1/2 in.)

Incidence, 5 degrees

Length, 19•5 m. (63 ft. 11 1/2 in.)

Height, 6•35 m. (20 ft. 10 in.)

Tail gap, 1•5 m. (4 ft. 11 in.)

Wheel diameter, 1•3 m. (4 ft. 3 in.)

Propeller diameter, 5•2 m. (17 ft.)

Propeller centres, 7•82 m. (25 ft. 8 in.)

Propeller pitch, 3 m. (9 ft. 10 in.)

Areas:

Wings, 260 sq. m. (2798 sq. ft.)

Ailerons, 4-4 sq. m. (47 sq. ft.)

Tailplane, 14•0 sq. m. (151 sq. ft.)

Elevator, 8•5 sq. m. (92 sq. ft.)

Rudders, 2•2 sq. m. (24 sq. ft.)

Weights:

Empty, 9000 kg. (19,845 lb.)

Useful load, 3700 kg. (8158 lb.)

Loaded, 12,700 kg. (28,003 lb.)

Wing Loading: 49 kg./sq. m. (10-1 lb./sq. ft.)

Performance: Not known

Fuel: 2750 litres (605 Imp. Gals.)

Armament: Provision for five machine-guns

Service Use: None

By virtue of the experience gained building twin-engined bombers, the Allgemeine Elektrizitats Gesellschaft (AEG) was included in the ambitious R-plane programme of 1916 along with SSW, Schutte-Lanz, Albatros, Aviatik and others. At the time, two giant bombers were ordered, designated R.I 21/16 and 22/16 and followed by an order for an additional six R.I machines numbered R.59 to R.64. Only one aircraft, the R.21, was flown before the end of hostilities. The R.I was born of much engineering skill and technical know-how as represented by AEG's staff of experienced engineers. Oberleutnant Bruckmann, former test pilot of the DFW R.I, was in charge of the venture established by AEG on 1 January 1917. Ing. Sander, formerly with DFW and SSW, was chief engineer, and his assistants were Dipl.-Ing. Werner Zorn, who also had been with DFW, and consultant Prof. Oesterlein of the Technische Hochschule, Brunswick. Design of the R.21 began in a rented eight-room flat in Berlin. An assembly shed was erected next to the Rumpler factory in Johannisthal. In the autumn of 1917 the design bureau moved there to supervise the construction of the R.21.

The R.I's long embryonic period from early 1917 until its first flight on 14 June 1918 reflected careful design, attention to detail and many hours of extensive bench tests. No effort was spared to incorporate lessons learned from the earlier giants, and many improvements and innovations were tried. Particularly noteworthy were the electrically-operated tailplane trim controls, the all-steel fuselage and the mixed steel and duraluminium wings. One of the most obstinate problems, which, perhaps, was never really solved, was engine misalignment and transmission vibration in centrally-powered aircraft. To mitigate this effect the R.I was literally built around a massive reinforced engine mount which supported fuselage, wings, landing gear and engines.

The four 260 h.p. Mercedes D.IVa engines were each linked to the drive system through a combination leather cone and dog clutch, while a fifth clutch connected each bank of engines. The airscrews were driven by two heavy transmission shafts running from a central gear-box to the propeller gear-box mounted between the wings. Articulated, sliding and universal joints were fitted to all connections to compensate for play and misalignment.

All four engines were started with a single Bosch inertia starter by first starting one engine and then "clutch-starting" the remainder. The exhaust gases were led into two large manifolds that were mounted in an indentation running along each side of the engine-room, permitting the exhaust system to operate in the airstream. Originally each engine had its own radiator bolted to the fuselage side, but later these were replaced by two large radiators composed of four separate units mounted on the centre-section struts. For a time, the AEG R.I was driven by four-bladed propellers, but these were soon replaced by two-bladed ones.

Cable-braced steel tubing was used exclusively on the frame-work of the fuselage. It was covered from the nose to the rear of the engine-room with plywood, the remainder was fabric-covered. The layout was typical of central-powered R-planes, with the exception that the pilots' cabin was situated aft of engines and wings. From this position it was considered easier for the pilot to judge his height during the critical touch-down phase, but this configuration, although tried in other R-planes, did not find favour with the crews.

The observer's cabin in the nose could be reached from the ground by a retractable ladder or through the engine-room directly aft. The cabin was fitted with glass windows to allow unobstructed vision to all sides. A spacious machine-gun post capable of holding two men was directly above the observer's cabin. The pilots' position was reached by stepping aft from the observer's cabin through a sliding door, passing through the engine-room (which was situated directly above the landing gear) between the engines on a small catwalk, and then climbing a small ladder to the cockpit. The cockpit seated two pilots and was fully-equipped with standard instruments, dual controls and the like. An engine telegraph similar in operation to those aboard ship, consisting of repeating pointers, provided communication between pilots and engine crew. The wireless cabin was located a few feet behind the cockpit, beneath the dorsal machine-gun post. The large windows on each side of the cabin indicated that beam machine-guns may have been considered. A ventral gun position was located in the floor.

The first R.I version had a curious semi-enclosed cabin which was later modified to a simple open cockpit for better visibility, and the enclosed dorsal gun position was replaced by a standard open gun ring. After modifying the cockpit, the fuselage had its greatest dimensions at this point, a depth of approximately 10 feet and a width of 6 feet.

The wing structure consisted of two chrome-nickel steel tube spars supporting duraluminium wing ribs, cable-braced throughout. Later AEG projects were to use rectangular aluminium girder spars designed and fabricated by Zeppelin-Werke, Lindau (Dornier), pioneers in this method of construction. The three-bay biplane wing structure was of equal span and chord. A curious feature was that the angle of incidence was washed-out towards the tips, giving the wings an unusual twisted appearance. This practice was fairly common on German aircraft of the period and was supposed to improve lateral control.

The controls of the R.I were unconventional, and it is a pity that only scant information is available. The elevator, for instance, was a forerunner of the all-flying tail of supersonic jets today. It was mounted some 5 feet over the tailplane, which itself could be electrically trimmed plus or minus several degrees. Two rudders were mounted between the elevator and tail plane out in the slipstream. Originally the gap between the two horizontal surfaces had been smaller, but after initial flight tests it was modified to improve control by adding more area to fin and rudders. The ailerons, rather than forming an integral part of the wing, were hinged to the outer two rear wing struts at a position midway between the wings. Like the high-set slab elevator, the aileron position was an innovation to avoid loss of control at critical angles of attack, particularly while landing.

The main landing wheels consisted of two wide-spoked hubs, each fitted with three tyres. Attached to each end of the main axle by a ball joint was an auxiliary landing gear, a kind of safety device that came into action only during a hard landing or sudden lurch that might throw the aircraft to one side.

The engine were ground tested on 23 and 30 May 1918. One engine with a broken connecting rod had to be replaced. On it first flight on 14 June 1918 the R.21, carrying a useful load of 1190 kg., flew for 27 minutes and climbed to 100 metres in a little under 10 minutes. The maiden flight was not without difficulties. With the engines throttled back the aircraft proved to be extremely tail heavy, even with full-down elevator the nose continued to rise. Only by shifting all available weight to the front was a safe landing made possible. After this initial flight the R.21 was modified as already described. It was hoped to have the work completed by 15 July 1918.

After a number of test flights it was determined that the propeller were not suitable. Additional sections were glued on at the propeller factory. Dipl.-Ing. Zorn warned Bruckmann that at least ten days would be required for the glue to set, but after only four days on 3 September 1918 Bruckmann ordered the propellers fitted to complete the urgent test programme. About an hour after the start a propeller flew apart, causing the cardan shaft to tear loose and shatter the centre-section structure. The R.21 broke up in the air over Rudow, killing seven men, including Bruckmann, Lt. Otto Reichardt (formerly commander of the R.13) and Lt. Dr. Oskar Wittenstein, both pre-war pilots attached to the Kommando-Riesenflugzeug-Abteilungen. Max Fiedler, who was flying escort in a Rumpler C.I, remembers the accident as follows:

I recall being slightly over the R.21 at about 6000 feet, when Bruckmann celebrating the event waved a cognac bottle as the R.21 swung into a left and then a right bank. There was a flutter and suddenly the wings folded back. It was a frightful sight.

Work on the partially completed R.22 was immediately halted until the cause of the catastrophe could be determined and fully evaluated by Idflieg.

An Idflieg document of 15 March 1918 listed these projected delivery dates for the AEG R.I aircraft: R.21 in April, R.22 and R.59 in June, R.60 in July, R.61 in September, R.62 in October 1918. The delivery dates of the R.63 and R.64 were not listed. In spite of this optimistic schedule, only the R.21 as completed. The R.22 (which was subject of discussions between Idflieg and AEG concerning an increase in wing area as late as 5 November 1918) was partially completed at the end of the war, but not enough to prevent it from being scrapped. Only portions of the R.59 to 64 series were begun, and after the war three R.I fuselage nose sections were photographed in the AEG scrap yard.

Like SSW, AEG possessed enough resources to weather the post-war period, and it is today among the largest of German electrical concerns.

Colour Scheme and Markings

The overall finish was the standard printed camouflage pattern. The design consisted of a repeated pattern of irregular polygons of five or six dull colours, such as grey, mauve, sage green, purple, blue and black. The actual colours and patterns varied with the sources of supply of the different aircraft manufacturers, but were all required to conform to a general standard set by Idflieg. After covering, the fabric was clear doped so that the printed pattern showed through. Latin crosses were painted on the wingtips, fuselage sides and rudders. The first version of the R.I had the early 1918 form of the Latin cross with short, broad arms, but the usual wide white outline was reduced to a thin white band. The final version of the R.I carried the standard Latin cross in use at the end of the war.

SPECIFICATIONS

Type: AEG R.I

Manufacturer: Allgemeine Elektrizitats Gesellschaft, Henningsdorf near Berlin

Engines: Four 260 h.p. Mercedes D.IVa engines

Propeller Revolutions: 750 r.p.m.

Dimensions: Span, 36 m. (118 ft. 1 1/2 in)

Chord, 3•8 m. (12 ft. 6 in.)

Gap, 4•5 to 4 m. (14 ft. 9 in. to 13 ft. 1 1/2 in.)

Incidence, 5 degrees

Length, 19•5 m. (63 ft. 11 1/2 in.)

Height, 6•35 m. (20 ft. 10 in.)

Tail gap, 1•5 m. (4 ft. 11 in.)

Wheel diameter, 1•3 m. (4 ft. 3 in.)

Propeller diameter, 5•2 m. (17 ft.)

Propeller centres, 7•82 m. (25 ft. 8 in.)

Propeller pitch, 3 m. (9 ft. 10 in.)

Areas:

Wings, 260 sq. m. (2798 sq. ft.)

Ailerons, 4-4 sq. m. (47 sq. ft.)

Tailplane, 14•0 sq. m. (151 sq. ft.)

Elevator, 8•5 sq. m. (92 sq. ft.)

Rudders, 2•2 sq. m. (24 sq. ft.)

Weights:

Empty, 9000 kg. (19,845 lb.)

Useful load, 3700 kg. (8158 lb.)

Loaded, 12,700 kg. (28,003 lb.)

Wing Loading: 49 kg./sq. m. (10-1 lb./sq. ft.)

Performance: Not known

Fuel: 2750 litres (605 Imp. Gals.)

Armament: Provision for five machine-guns

Service Use: None

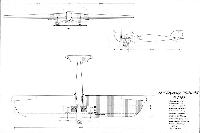

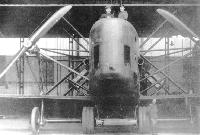

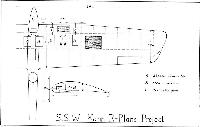

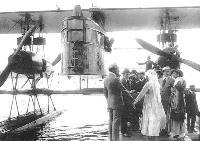

AEG R.I. 21/16 modified to have two-bladed propeller. Obltn. Bruckmann is the tallest man in pilot's uniform beneath the left hand propeller.

The massive AEG R.I 21/16 in its final form. A centrally-powered machine with four 260 h.p. Mercedes D.IVa engines.

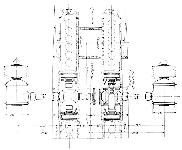

AEG R-plane Projects

AEG received a contract in 1916-17 to build the AEG R.II 205/16. This design fell into the same category as the Junkers and Staaken thick-wing all-metal monoplane projects intended for day-bombing use.

On 17 January 1918 the Daimler-Motoren-Gesellschaft booked an Idflieg order for a complete power system consisting of eight 260 h.p. Mercedes D.IVa engines, six double-cone couplings, two transverse transmission drives and a flywheel mounted ahead of the starter coupling. This system was intended for the AEG R.II, which, according to Daimler, had the following particulars: wingspan, 45•9 m., length 24•2 m., wing area 325 sq. m. Empty weight was estimated as 12,480 kg. (plus 530 kg. not identified). Fuel to be stored in 12 tanks and weighed 5000 kg. The tractor propellers were two-bladed with a diameter of 5•20 m.; the four-bladed pusher propellers had a diameter of 4•80 m. Estimated top speed was 145 km.h. and climb for 1000, 2000 and 3000 m. was 12, 26 and 41 minutes respectively. Duration was 12 hours for a range of 1600 kilometres. The Dornier works at Lindau had constructed several all-metal wing spars that AEG load tested for their monoplane project.

Another AEG R-plane project, mentioned in official reports in September 1918, had four 245-h.p. Maybach Mb.IVa engines and one 500 hp. Benz Bz.VI or Maybach Mb.VI driving a total of three propellers. The report stated that the project would be held in abeyance for the time being.

The AEG R.II remained on the drawing boards, as did the AEG triplane project with four 500 h.p. Mercedes engines and a wingspan of 35 metres, not to be confused with but probably similar to the AEG-Aviatik project mentioned in the next chapter.

The Navy also ordered several AEG giant aircraft in 1917 and 1918, but virtually no information exists outside of a brief mention in an official Naval document. In October 1917 an order was placed with AEG for a biplane R-seaplane with four 245 h.p. Maybach Mb.IVa engines. The number initially assigned to this type was 2139, which was later changed to 9301. Marine Baumeister Neesen recalls that this type was basically a modified R.I equipped with floats.

Two more naval R-planes were ordered in January 1918, having the numbers 9302-9303. Their configuration is not known, other than that the engines were to be four 245 h.p. Maybach Mb.Iva engines.

AEG-Aviatik R-plane Project

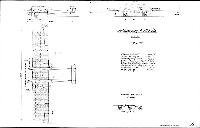

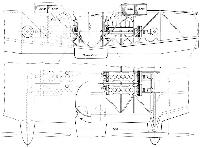

Toward the end of 1917 Idflieg, greatly influenced by the load-carrying capacity of the Caproni triplanes, fostered the construction of multi-engined triplanes, the only completed example of which was the LVG G.III. However, AEG and Aviatik undertook a joint project to build the largest R-plane envisioned at that time.

The experience of both organizations was enlisted in this ambitious project, construction of which, it is claimed, was actually started in Stettin but was halted by the Armistice. By the end of 1917 most of the test data concerning efficient triplane configurations had already been collected from wind-tunnel tests at Gottingen. During the early design stage Idflieg suggested that it might be feasible to build a 4 to 1 flying scale model to test the performance characteristics of the proposed giant. The model was to have 12-14 metre wingspan, an area of 40 square metres and a loaded weight of 1400 kg. However, the engine weight would be far in excess of the 4 to 1 scale ratio, forcing the designer, Ludwig Maurer, the Chief Engineer of Aviatik, to the conclusion that a model aircraft, in this case, would be unfeasible. Not until the advent of high power-to-weight ratio engines, would scale models become a tool to test the characteristics of larger aircraft.

The partially completed aircraft was centrally powered and presented another solution of the engine arrangement problem; in this instance the engines were mounted athwartship side by side, and each drove a single propeller by means of an extended shaft leading through the middle wing to a right-angle bevel gear-box, which eliminated the usual bulky gear and clutch systems. This and the DFW power transmission were the simplest of the central-engine systems. Although eight 250 h.p. engines were initially proposed, the advent of the 530 h.p. 12 cylinder Benz Bz.VI engine permitted the use of only four engines to attain the required 2000 horse-power. These were to be supercharged by a 120 h.p. Mercedes D.II engine driving a centrifugal compressor. Four bullet-proof and fire-resistant tank were mounted beneath the engine bearers and had a total capacity for 8 hours' flight. The radiators were mounted on the centre wing in the slipstream of the tractor propellers.

As usual, the nose was fitted with a large machine-gun post which doubled as an open navigating position for the aircraft commander-navigator. This was followed by a fairly large closed navigation cabin, above and behind which was situated the roomy open pilots' cockpit, arranged to afford a clear view in most directions. Underneath the cockpit it was planned to have a wireless station equipped with wireless receiver, sender, sound amplifier and a dynamo which would also serve to provide illumination for night flying. Commands would be transmitted throughout the aircraft by a machine telegraph system and pneumatic tubes. A walkway made it possible to step from the wireless station into the engine-room through a large sound-proofed bulkhead and walk to the rear of the aircraft.

The fuselage was to be constructed of four massive wooden box longerons with steel-tube cross struts and engine bearers. The wing structure was heavily staggered, reminiscent of the experimental Nieuport triplanes and shown to be an efficient arrangement by the Gottingen wind-tunnel tests. The lower wing was attached to the fuselage by a streamlined extension containing the bombardier's cabin. The aircraft was studded with machine-gun posts: one in the nose, two immediately behind the cockpit (one wonders how the pilots would have liked this); two behind the wings; one in the extreme tail, and perhaps several on the underside of the fuselage. Each crew member was to be provided with a parachute stowed near his post so that it would be instantly accessible.

The landing gear used steel springs a shock absorber and the wheel were possibly of the steel-band type developed by Linke-Hofmann. The tail skid consisted of a sprung-wheel carriage which could be steered.

Although the AEG-Aviatik R-plane project was described in detail by the German post-war aviation press, nothing was said about its degree of completion, other than that it was "partially completed". It is very doubtful, however, if the project advanced materially beyond the barest preliminaries. The AEG-Aviatik R-plane belonged to the third generation of giant bombers in the same category as the massive Staaken R.VIII and R.IX, AEG R.II and DFW R.III.

SPECIFICATIONS

Type: AEG-Aviatik R-Plane Project

Manufacturer: AEG-Aviatik joint venture, Stettin

Engines: Four 530 h.p. Benz Bz.VI engines

Dimensions:

Span, 55 m. (180 ft. 5 in.)

Length, 27 m. (88 ft. 7 in.)

Height, 8•8 m. (28 ft. 10 in.)

Propeller diameter, 6 m. (19ft. 8 in.)

Areas: Wings, 620 sq. m. (6671 sq. ft.)

Weights (Est.):

Empty, 15,000 kg. (33,075 lb.)

Useful load, 7000 kg. (15,435 lb.)

Loaded, 22,000 kg. (48,510 lb.)

Performance (Est.):

Maximum speed, 145-150 km/h. (90•1 - 93•2 m.p.h.) at 3000 m. (9843 ft.)

Ceiling, 5000 m. (16,405 ft.) in 120 mins.

Duration, 8 hrs.

Armament: Provision for six or seven machine-guns

AEG received a contract in 1916-17 to build the AEG R.II 205/16. This design fell into the same category as the Junkers and Staaken thick-wing all-metal monoplane projects intended for day-bombing use.

On 17 January 1918 the Daimler-Motoren-Gesellschaft booked an Idflieg order for a complete power system consisting of eight 260 h.p. Mercedes D.IVa engines, six double-cone couplings, two transverse transmission drives and a flywheel mounted ahead of the starter coupling. This system was intended for the AEG R.II, which, according to Daimler, had the following particulars: wingspan, 45•9 m., length 24•2 m., wing area 325 sq. m. Empty weight was estimated as 12,480 kg. (plus 530 kg. not identified). Fuel to be stored in 12 tanks and weighed 5000 kg. The tractor propellers were two-bladed with a diameter of 5•20 m.; the four-bladed pusher propellers had a diameter of 4•80 m. Estimated top speed was 145 km.h. and climb for 1000, 2000 and 3000 m. was 12, 26 and 41 minutes respectively. Duration was 12 hours for a range of 1600 kilometres. The Dornier works at Lindau had constructed several all-metal wing spars that AEG load tested for their monoplane project.

Another AEG R-plane project, mentioned in official reports in September 1918, had four 245-h.p. Maybach Mb.IVa engines and one 500 hp. Benz Bz.VI or Maybach Mb.VI driving a total of three propellers. The report stated that the project would be held in abeyance for the time being.

The AEG R.II remained on the drawing boards, as did the AEG triplane project with four 500 h.p. Mercedes engines and a wingspan of 35 metres, not to be confused with but probably similar to the AEG-Aviatik project mentioned in the next chapter.

The Navy also ordered several AEG giant aircraft in 1917 and 1918, but virtually no information exists outside of a brief mention in an official Naval document. In October 1917 an order was placed with AEG for a biplane R-seaplane with four 245 h.p. Maybach Mb.IVa engines. The number initially assigned to this type was 2139, which was later changed to 9301. Marine Baumeister Neesen recalls that this type was basically a modified R.I equipped with floats.

Two more naval R-planes were ordered in January 1918, having the numbers 9302-9303. Their configuration is not known, other than that the engines were to be four 245 h.p. Maybach Mb.Iva engines.

AEG-Aviatik R-plane Project

Toward the end of 1917 Idflieg, greatly influenced by the load-carrying capacity of the Caproni triplanes, fostered the construction of multi-engined triplanes, the only completed example of which was the LVG G.III. However, AEG and Aviatik undertook a joint project to build the largest R-plane envisioned at that time.

The experience of both organizations was enlisted in this ambitious project, construction of which, it is claimed, was actually started in Stettin but was halted by the Armistice. By the end of 1917 most of the test data concerning efficient triplane configurations had already been collected from wind-tunnel tests at Gottingen. During the early design stage Idflieg suggested that it might be feasible to build a 4 to 1 flying scale model to test the performance characteristics of the proposed giant. The model was to have 12-14 metre wingspan, an area of 40 square metres and a loaded weight of 1400 kg. However, the engine weight would be far in excess of the 4 to 1 scale ratio, forcing the designer, Ludwig Maurer, the Chief Engineer of Aviatik, to the conclusion that a model aircraft, in this case, would be unfeasible. Not until the advent of high power-to-weight ratio engines, would scale models become a tool to test the characteristics of larger aircraft.

The partially completed aircraft was centrally powered and presented another solution of the engine arrangement problem; in this instance the engines were mounted athwartship side by side, and each drove a single propeller by means of an extended shaft leading through the middle wing to a right-angle bevel gear-box, which eliminated the usual bulky gear and clutch systems. This and the DFW power transmission were the simplest of the central-engine systems. Although eight 250 h.p. engines were initially proposed, the advent of the 530 h.p. 12 cylinder Benz Bz.VI engine permitted the use of only four engines to attain the required 2000 horse-power. These were to be supercharged by a 120 h.p. Mercedes D.II engine driving a centrifugal compressor. Four bullet-proof and fire-resistant tank were mounted beneath the engine bearers and had a total capacity for 8 hours' flight. The radiators were mounted on the centre wing in the slipstream of the tractor propellers.

As usual, the nose was fitted with a large machine-gun post which doubled as an open navigating position for the aircraft commander-navigator. This was followed by a fairly large closed navigation cabin, above and behind which was situated the roomy open pilots' cockpit, arranged to afford a clear view in most directions. Underneath the cockpit it was planned to have a wireless station equipped with wireless receiver, sender, sound amplifier and a dynamo which would also serve to provide illumination for night flying. Commands would be transmitted throughout the aircraft by a machine telegraph system and pneumatic tubes. A walkway made it possible to step from the wireless station into the engine-room through a large sound-proofed bulkhead and walk to the rear of the aircraft.

The fuselage was to be constructed of four massive wooden box longerons with steel-tube cross struts and engine bearers. The wing structure was heavily staggered, reminiscent of the experimental Nieuport triplanes and shown to be an efficient arrangement by the Gottingen wind-tunnel tests. The lower wing was attached to the fuselage by a streamlined extension containing the bombardier's cabin. The aircraft was studded with machine-gun posts: one in the nose, two immediately behind the cockpit (one wonders how the pilots would have liked this); two behind the wings; one in the extreme tail, and perhaps several on the underside of the fuselage. Each crew member was to be provided with a parachute stowed near his post so that it would be instantly accessible.

The landing gear used steel springs a shock absorber and the wheel were possibly of the steel-band type developed by Linke-Hofmann. The tail skid consisted of a sprung-wheel carriage which could be steered.

Although the AEG-Aviatik R-plane project was described in detail by the German post-war aviation press, nothing was said about its degree of completion, other than that it was "partially completed". It is very doubtful, however, if the project advanced materially beyond the barest preliminaries. The AEG-Aviatik R-plane belonged to the third generation of giant bombers in the same category as the massive Staaken R.VIII and R.IX, AEG R.II and DFW R.III.

SPECIFICATIONS

Type: AEG-Aviatik R-Plane Project

Manufacturer: AEG-Aviatik joint venture, Stettin

Engines: Four 530 h.p. Benz Bz.VI engines

Dimensions:

Span, 55 m. (180 ft. 5 in.)

Length, 27 m. (88 ft. 7 in.)

Height, 8•8 m. (28 ft. 10 in.)

Propeller diameter, 6 m. (19ft. 8 in.)

Areas: Wings, 620 sq. m. (6671 sq. ft.)

Weights (Est.):

Empty, 15,000 kg. (33,075 lb.)

Useful load, 7000 kg. (15,435 lb.)

Loaded, 22,000 kg. (48,510 lb.)

Performance (Est.):

Maximum speed, 145-150 km/h. (90•1 - 93•2 m.p.h.) at 3000 m. (9843 ft.)

Ceiling, 5000 m. (16,405 ft.) in 120 mins.

Duration, 8 hrs.

Armament: Provision for six or seven machine-guns

Ago R-plane Project

The "Rapport Technique", more commonly known as the "Inter-Allied Report", was the official publication of the Inter-Allied Aeronautical Control Commission, which was responsible for the control of aeronautical activities in Germany after the war. The "Inter-Allied Report" does contain numerous errors; yet surprisingly many of its "errors" have been proven correct by subsequent research into German wartime activities. The report does contain reference to an R-plane designed by Ago-Flugzeugwerke G.m.b.H. during the war.

Ago was awarded a war patent (No. 310,096) on 30 September 1919 which describes an aircraft with three centrally mounted engines coupled to a common gear-box, which in turn drove four propellers spaced along the trailing edge of the wing. In April 1918, Ago ordered a test assembly from Daimler-Motoren-Gesellschaft comprising three 160 h.p. Mercedes D.IIIav engines and suitable clutches connected to a right angle gear-box having two propeller drive shafts. It was planned to bench test this arrangement prior to using larger 500 h.p. engines. From available records, it seems Ago was considering a 3000 h.p. R-plane driven by four propellers. This project was in the preliminary design stage when the war ended.

The "Rapport Technique", more commonly known as the "Inter-Allied Report", was the official publication of the Inter-Allied Aeronautical Control Commission, which was responsible for the control of aeronautical activities in Germany after the war. The "Inter-Allied Report" does contain numerous errors; yet surprisingly many of its "errors" have been proven correct by subsequent research into German wartime activities. The report does contain reference to an R-plane designed by Ago-Flugzeugwerke G.m.b.H. during the war.

Ago was awarded a war patent (No. 310,096) on 30 September 1919 which describes an aircraft with three centrally mounted engines coupled to a common gear-box, which in turn drove four propellers spaced along the trailing edge of the wing. In April 1918, Ago ordered a test assembly from Daimler-Motoren-Gesellschaft comprising three 160 h.p. Mercedes D.IIIav engines and suitable clutches connected to a right angle gear-box having two propeller drive shafts. It was planned to bench test this arrangement prior to using larger 500 h.p. engines. From available records, it seems Ago was considering a 3000 h.p. R-plane driven by four propellers. This project was in the preliminary design stage when the war ended.

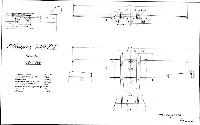

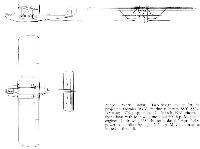

Albatros G.I

The Ostdeutsche Albatroswerke G.m.b.H. was founded on 27 April 1914 in Schneidemuhl by Otto Wiener and Dr. Walter Huth, the latter also the founder of the original Albatros concern in Johannisthal. (The company abbreviation initially was "Albs" and the correct designation of the licence-built R-planes was Staaken R.Vl (Albs) 36/16. Later in the war the company abbreviation was changed to "OAW", as in Albatros D.Va (OAW).) Although OAW maintained close ties with Albatros, it remained an independent company until October 1917, when it became a branch of the Albatros concern. OAW concerned itself almost totally with the construction of licence-built aircraft (exclusively Albatros types), but did produce a few aircraft of its own design. Among these was a four-engined bomber known as the Albatros G.I (company designation L4), which was designed by an engineer named Grohmann, who was appreciably influenced by the Sikorsky four-engined bomber. The G.I fell into the same grouping as the Union, SSW-Forssman and Daimler bombers; that is, they were early aircraft of considerable size, but their engine configuration did not permit in-flight servicing. Four 120 h.p. Mercedes D.II engines powered the G.I, which had a wingspan of 27 metres. These were mounted on the lower wing in large full-enclosed nacelles and drove four tractor propellers. The Swiss pilot Alexander Hipleh flew the G.I on its maiden flight on 31 January 1916. The G.I was subsequently developed into the Albatros G.II and G.III, which bore a certain family resemblance to the G.I although they were twin-engined bombers. Further details concerning the G.I are not known.

]n early 1917 OAW received a contract to build three Staaken R.VI bombers under licence. The first of the series, numbered R.36 to R.38, was begun in May 1917 and the last machine was delivered in May 1918. The Staaken R.VI chapter contains additional information concerning these machines.

SPECIFICATIONS

Type: Albatros G.I

Manufacturer: Ostdeutsche Albatroswerke G.M.b.H., Schneidemuhl

Engines: Four 120 h.p. Mercedes D.II engines

Dimensions:

Span 27•3 m. (89 ft. 6 1/2 in.)

Chord 2•75 m. (9 ft. 1/2 in.)

Fuselage Length 12•0 m. (39 ft. 4 1/4 in.)

Areas:

Wing 138 sq. m. (1485 sq. ft.)

Ailerons 3•03 sq. m. (33 sq. ft.)

Tailplane 6•6 sq. m. (71 sq. ft.)

Rudder 1•5 sq. m. (16 sq. ft.)

Fin 1•92 sq. m. (20 sq. ft.)

Weights: Empty 3452 kg. (7610 lb.)

Loaded 4319 kg. (9522 lb.)

Wing Loading: 31•3 kg./sq. m. (6-4 lb./sq. ft.)

Performance: Climb, 2000 m. (6562 ft.) in 60 mins.

The Ostdeutsche Albatroswerke G.m.b.H. was founded on 27 April 1914 in Schneidemuhl by Otto Wiener and Dr. Walter Huth, the latter also the founder of the original Albatros concern in Johannisthal. (The company abbreviation initially was "Albs" and the correct designation of the licence-built R-planes was Staaken R.Vl (Albs) 36/16. Later in the war the company abbreviation was changed to "OAW", as in Albatros D.Va (OAW).) Although OAW maintained close ties with Albatros, it remained an independent company until October 1917, when it became a branch of the Albatros concern. OAW concerned itself almost totally with the construction of licence-built aircraft (exclusively Albatros types), but did produce a few aircraft of its own design. Among these was a four-engined bomber known as the Albatros G.I (company designation L4), which was designed by an engineer named Grohmann, who was appreciably influenced by the Sikorsky four-engined bomber. The G.I fell into the same grouping as the Union, SSW-Forssman and Daimler bombers; that is, they were early aircraft of considerable size, but their engine configuration did not permit in-flight servicing. Four 120 h.p. Mercedes D.II engines powered the G.I, which had a wingspan of 27 metres. These were mounted on the lower wing in large full-enclosed nacelles and drove four tractor propellers. The Swiss pilot Alexander Hipleh flew the G.I on its maiden flight on 31 January 1916. The G.I was subsequently developed into the Albatros G.II and G.III, which bore a certain family resemblance to the G.I although they were twin-engined bombers. Further details concerning the G.I are not known.

]n early 1917 OAW received a contract to build three Staaken R.VI bombers under licence. The first of the series, numbered R.36 to R.38, was begun in May 1917 and the last machine was delivered in May 1918. The Staaken R.VI chapter contains additional information concerning these machines.

SPECIFICATIONS

Type: Albatros G.I

Manufacturer: Ostdeutsche Albatroswerke G.M.b.H., Schneidemuhl

Engines: Four 120 h.p. Mercedes D.II engines

Dimensions:

Span 27•3 m. (89 ft. 6 1/2 in.)

Chord 2•75 m. (9 ft. 1/2 in.)

Fuselage Length 12•0 m. (39 ft. 4 1/4 in.)

Areas:

Wing 138 sq. m. (1485 sq. ft.)

Ailerons 3•03 sq. m. (33 sq. ft.)

Tailplane 6•6 sq. m. (71 sq. ft.)

Rudder 1•5 sq. m. (16 sq. ft.)

Fin 1•92 sq. m. (20 sq. ft.)

Weights: Empty 3452 kg. (7610 lb.)

Loaded 4319 kg. (9522 lb.)

Wing Loading: 31•3 kg./sq. m. (6-4 lb./sq. ft.)

Performance: Climb, 2000 m. (6562 ft.) in 60 mins.

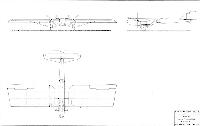

Aviatik R.III Civil Project

The name Aviatik had already achieved considerable fame as the trade-mark of the Automobil und Aviatik A.G. in Leipzig-Heiterblick, a manufacturer of a line of successful pre-war aircraft. During the war, Aviatik mass produced trainer and observation biplanes, a handful of fighters and Gotha G.VII bombers under licence.

The firm also made a large contribution to the R-plane programme as the most important licence manufacturer of Staaken R-planes. The initial order was for three Staaken R.VI machines numbered R.33/16 to R.35/16, the first of which was delivered in September 1917. Unofficially this series was known as the Aviatik R.I in company literature disseminated by Aviatik after the war. There is neither record nor reason to substantiate that the R.I designation was ever officially sanctioned. The first series was followed by a second batch of three Staaken R.VI machines numbered R.52/17 to R.54/17. These aircraft (known internally as Aviatik R.II) were modified to some extent by Aviatik, and in at least one instance the stepped, glassed-in cockpit was eliminated and replaced by a front-gun position and open cockpit raised flush with the upper longerons. The first aircraft (R.52) was initially powered by four 300 h.p. Basse & Selve BuS.IVa engines. These gave trouble during ground tests conducted on 7 May 1918, and were replaced by the more reliable, but less powerful, 245 h.p. Maybach Mb.IVa engines. The acceptance flight took place on 5 June, and Idflieg promised official acceptance on 28 June, provided that various defects were remedied. However, such was the demand for aircraft that the R.52 left for Rfa 500 at Morville on 20 June, stopping en route at Hannover due to poor weather conditions. The second machine, R.53, was delivered in July 1918, and was assigned to Rea Cologne as a trainer. The completion of the last Aviatik-built Staaken R.VI was delayed until October pending a decision whether or not to install a fifth Maybach in the nose. The final series built by Aviatik under licence was the Staaken R.XVI, R.49/17 to R.51/17 (known internally as Aviatik R.III), of which only the R.49 was delivered prior to the war's close.

In early 1919 Aviatik had the three-quarters completed R.50 and R.51 on its hands, and it received permission to complete these as commercial transports, but only the R.50 was finished (see Staaken R.XVI chapter).

In hopes of entering the commercial passenger and air-mail aircraft business, Aviatik publicized the Aviatik R.III Civil Transport. The R.III received full coverage in the aeronautical Press, and beautifully retouched photographs gave the impression that the machine was actually built. However, the civil adaptation did not advance farther than the design stage. The fuselage was redesigned to accommodate eighteen passengers in seats placed back-to-back. A small open cupola was situated in the nose, followed by an enclosed observation cabin. The pilots were located in an open cockpit well ahead of the wings. The four tandem, geared 250 h.p. Benz engines were mounted on streamlined pylons above the lower wing. These pylons carried enough fuel for 7 hours maximum duration, and the engines were serviceable in flight. The wing area was increased by keeping the chord constant throughout the span. The crew consisted of an aircraft captain, two pilots, two engineers and a steward.

Engineers von Platen and Rau, both of whom had earlier been closely associated with the SSW R-plane programme (Rau as a member of Idflieg), later joined Aviatik to work on licence machines and advanced projects such as the R.III.

SPECIFICATIONS

Type: Aviatik R.III (Civil Project)

Manufacturer: Automobil & Aviatik A.G., Leipzig-Heiterblick

Engines: Four 250 h.p. Benz engines

Dimensions:

Span, 43•5 m. (142ft. 9 in.)

Length, 22•5 m. (73 ft. 10 in.)

Height, 6•5 m. (21ft. 3 1/2 in.)

Weights (Est.).

Empty, 9000 kg. (19,845 lb.)

Fuel and crew, 1800 kg. (3969 lb.)

Disposable load, 1800 kg. (3969 lb.)

Loaded, 12,600 kg. (27,783 lb.)

Performance (Est.):

Maximum speed, 125 km.h. (78 m.p.h.) at 2500 m. (8200 ft.)

Climb, 3500 m. (11 ,483ft.) in 100 mins.

Ceiling, 4000 m. (13,124 ft.)

Duration (max.), 7 hrs.

Range, 875 km. (544 miles)

The name Aviatik had already achieved considerable fame as the trade-mark of the Automobil und Aviatik A.G. in Leipzig-Heiterblick, a manufacturer of a line of successful pre-war aircraft. During the war, Aviatik mass produced trainer and observation biplanes, a handful of fighters and Gotha G.VII bombers under licence.

The firm also made a large contribution to the R-plane programme as the most important licence manufacturer of Staaken R-planes. The initial order was for three Staaken R.VI machines numbered R.33/16 to R.35/16, the first of which was delivered in September 1917. Unofficially this series was known as the Aviatik R.I in company literature disseminated by Aviatik after the war. There is neither record nor reason to substantiate that the R.I designation was ever officially sanctioned. The first series was followed by a second batch of three Staaken R.VI machines numbered R.52/17 to R.54/17. These aircraft (known internally as Aviatik R.II) were modified to some extent by Aviatik, and in at least one instance the stepped, glassed-in cockpit was eliminated and replaced by a front-gun position and open cockpit raised flush with the upper longerons. The first aircraft (R.52) was initially powered by four 300 h.p. Basse & Selve BuS.IVa engines. These gave trouble during ground tests conducted on 7 May 1918, and were replaced by the more reliable, but less powerful, 245 h.p. Maybach Mb.IVa engines. The acceptance flight took place on 5 June, and Idflieg promised official acceptance on 28 June, provided that various defects were remedied. However, such was the demand for aircraft that the R.52 left for Rfa 500 at Morville on 20 June, stopping en route at Hannover due to poor weather conditions. The second machine, R.53, was delivered in July 1918, and was assigned to Rea Cologne as a trainer. The completion of the last Aviatik-built Staaken R.VI was delayed until October pending a decision whether or not to install a fifth Maybach in the nose. The final series built by Aviatik under licence was the Staaken R.XVI, R.49/17 to R.51/17 (known internally as Aviatik R.III), of which only the R.49 was delivered prior to the war's close.

In early 1919 Aviatik had the three-quarters completed R.50 and R.51 on its hands, and it received permission to complete these as commercial transports, but only the R.50 was finished (see Staaken R.XVI chapter).

In hopes of entering the commercial passenger and air-mail aircraft business, Aviatik publicized the Aviatik R.III Civil Transport. The R.III received full coverage in the aeronautical Press, and beautifully retouched photographs gave the impression that the machine was actually built. However, the civil adaptation did not advance farther than the design stage. The fuselage was redesigned to accommodate eighteen passengers in seats placed back-to-back. A small open cupola was situated in the nose, followed by an enclosed observation cabin. The pilots were located in an open cockpit well ahead of the wings. The four tandem, geared 250 h.p. Benz engines were mounted on streamlined pylons above the lower wing. These pylons carried enough fuel for 7 hours maximum duration, and the engines were serviceable in flight. The wing area was increased by keeping the chord constant throughout the span. The crew consisted of an aircraft captain, two pilots, two engineers and a steward.

Engineers von Platen and Rau, both of whom had earlier been closely associated with the SSW R-plane programme (Rau as a member of Idflieg), later joined Aviatik to work on licence machines and advanced projects such as the R.III.

SPECIFICATIONS

Type: Aviatik R.III (Civil Project)

Manufacturer: Automobil & Aviatik A.G., Leipzig-Heiterblick

Engines: Four 250 h.p. Benz engines

Dimensions:

Span, 43•5 m. (142ft. 9 in.)

Length, 22•5 m. (73 ft. 10 in.)

Height, 6•5 m. (21ft. 3 1/2 in.)

Weights (Est.).

Empty, 9000 kg. (19,845 lb.)

Fuel and crew, 1800 kg. (3969 lb.)

Disposable load, 1800 kg. (3969 lb.)

Loaded, 12,600 kg. (27,783 lb.)

Performance (Est.):

Maximum speed, 125 km.h. (78 m.p.h.) at 2500 m. (8200 ft.)

Climb, 3500 m. (11 ,483ft.) in 100 mins.

Ceiling, 4000 m. (13,124 ft.)

Duration (max.), 7 hrs.

Range, 875 km. (544 miles)

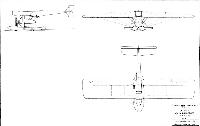

Daimler R.I and R.II

In the summer of 1915 the Daimler-Motoren-Gesellschaft A.G., manufacturers of the famous Mercedes engine, formed an aircraft construction division with hangars located at the airfield in Sindelfingen. In August they began construction of a four-engined bomber that was almost identical to the Union G.T. Daimler, having made the decision to begin aircraft production, had chosen the Union-design as its first product.

The Daimler R.I, as the Union-design was now called, was constructed under the direction of Baurat Rittberger and Ing. Karl Schopper (both formerly with Union) at the rather primitive and make-shift facilities at Sindelfingen. Most of the R.I and R.II parts were built by the Stuttgart firm of Schiedmayer and taken to Sindelfingen for assembly. The R.I fuselage was more robust than its predecessors, and the troublesome inverted engines were replaced by the reliable 160 h.p. Mercedes D.III engine. The R.I first flew in late 1915 at Sindelfingen. While engine problems had been eliminated, the airframe had to be strengthened more than once. At least three different wing assemblies were flight-tested between 1915 and 1917. A second R.I was constructed with a larger tail to improve directional control.

Idflieg was interested in the R.I, initially as an experimental type, later as a trainer for G-type bomber crews. Although the performance and flight characteristics of the Daimler R.I were not very promising, the aircraft were test flown until the middle of 1917. In November 1917 one G.I (as the R.I was now designated) was transferred to Idflieg.

Two examples of an improved version, the Daimler R.II, were constructed in the spring of 1916. (According to the Sindelfingen city archive and latest researches at the Daimler-Benz Archiv, a total of six R.II aircraft were built. Two were taken by Idflieg and four were crated in boxes for reasons unknown.) Outwardly more robust in appearance, the R.II was almost an exact duplicate of the R.I. The overall dimensions were similar, only the weight was slightly increased. A major change was the finely shaped nacelles, mounted between the wings and supported in the centre by a streamlined pylon. Both R.II bombers were taken over by Idflieg and remained on flight status until the middle of 1917 at Sindelfingen.

In 1916 the R.I and R.II were redesignated G.I and G.II, since they belonged to the same category as the four-engined Union G.I Albatros G.I and SSW-Forssman R-types: large in size, but engines not serviceable in flight. Records in the Daimler-Benz archives show that the R.I (G.I) and two R.II (G.II) bombers were numbered 478/15, 450/15 and 451/15 respectively. These numbers do not fit the R-plane numbering sequence, or the 1915 G-type sequence.

SPECIFICATIONS

Type: Daimler R.I

Manufacturer: Daimler-Motoren-Gesellschaft A.G., Sindelfingen

Engines: Four 160 h.p. Mercedes D.III engine

Dimensions:

Span, 21•08 m. (69 ft. 2 in.)

Length, 18•35 m. (60 ft. 2 1/2 in.)

Height, 3•80 m. (12 ft. 6 in.)

Areas: Wings, 73•62 sq. m. (792 sq. ft.)

Weights:

Empty, 2512 kg. (5538 lb.)

Loaded, 3630 kg. (8003 lb.)

Wing Loading: 49•3 kg./sq. m. (10,1 lb./sq. ft.)

Performance, Maximum Speed, 120 km.h. (74,6 m.p.h.)

Cruising Speed, 114 km.h. (70'8 m.p.h.)

Climb,

1000 m. (3281 ft.) in 16•8 mins.

1500 m. (4921 ft.) in 26•9 mins.

Ceiling, 3000 m. (9843 ft.)

Type: Daimler R.I (second version)

Manufacturer: Daimler-Motoren-Gesellschaft A.G., Sindelfingen

Engines: Four 160 h.p. Mercedes D.III engines

Dimensions: Span, 21,15 m. (69 ft. 4 in.)

Length, 18•20 m. (59 ft. 8 1/2 in.)

Height, 3•75 m. (12 ft. 3 1/2 in.)

Areas: Wings, 70•60 sq. m. (760 sq. ft.)

Weights:

Empty, 2510 kg. (5534 lb.)

Loaded, 3700 kg. (8157 lb.)

Wing Loading: 52-4 kg./sq. m. (10'7 lb./sq. ft.)

Performance: Maximum Speed, 119 km.h. (73,9 m.p.h.)

Cruising Speed, 114 km.h. (70'8 m.p.h.)

Climb,

1000 m. (3281 ft.) in 17•0 mins.

1500 m. (4921 ft.) in 28•0 min.

Ceiling, 3000 m. (9843 ft.)

Type: Daimler R.II

Manufacturer: Daimler-Motoren-Gesellschaft A.G., Sindelfingen

Engines: Four 160 h.p. Mercedes D.III engines

Dimensions: Span, 21 •26 m. (69 ft. 9 in.)

Length, 18-40 m. (60 ft. 4 in.)

Height, 3•80 m. (12 ft. 6 in.)

Areas: Wings, 74•80 sq. m. (805 sq. ft.)

Weights:

Empty, 2540 kg. (5600 lb.)

Loaded, 3680 kg. (8113 lb.)

Wing Loading: 49•3 kg.jsq. m. (10,1 lb./sq. ft.)

Performance: Maximum Speed, 123 km.h. (76-4 m.p.h.)

Cruising Speed, 120 km.h. (74'6 m.p.h.)

Climb,

1000 m. (3281 ft.) in 15•2 mins.

1500 m. (4921 ft.) in 25•0 mins.

Ceiling, 3000 m. (9843 ft.)

In the summer of 1915 the Daimler-Motoren-Gesellschaft A.G., manufacturers of the famous Mercedes engine, formed an aircraft construction division with hangars located at the airfield in Sindelfingen. In August they began construction of a four-engined bomber that was almost identical to the Union G.T. Daimler, having made the decision to begin aircraft production, had chosen the Union-design as its first product.

The Daimler R.I, as the Union-design was now called, was constructed under the direction of Baurat Rittberger and Ing. Karl Schopper (both formerly with Union) at the rather primitive and make-shift facilities at Sindelfingen. Most of the R.I and R.II parts were built by the Stuttgart firm of Schiedmayer and taken to Sindelfingen for assembly. The R.I fuselage was more robust than its predecessors, and the troublesome inverted engines were replaced by the reliable 160 h.p. Mercedes D.III engine. The R.I first flew in late 1915 at Sindelfingen. While engine problems had been eliminated, the airframe had to be strengthened more than once. At least three different wing assemblies were flight-tested between 1915 and 1917. A second R.I was constructed with a larger tail to improve directional control.

Idflieg was interested in the R.I, initially as an experimental type, later as a trainer for G-type bomber crews. Although the performance and flight characteristics of the Daimler R.I were not very promising, the aircraft were test flown until the middle of 1917. In November 1917 one G.I (as the R.I was now designated) was transferred to Idflieg.

Two examples of an improved version, the Daimler R.II, were constructed in the spring of 1916. (According to the Sindelfingen city archive and latest researches at the Daimler-Benz Archiv, a total of six R.II aircraft were built. Two were taken by Idflieg and four were crated in boxes for reasons unknown.) Outwardly more robust in appearance, the R.II was almost an exact duplicate of the R.I. The overall dimensions were similar, only the weight was slightly increased. A major change was the finely shaped nacelles, mounted between the wings and supported in the centre by a streamlined pylon. Both R.II bombers were taken over by Idflieg and remained on flight status until the middle of 1917 at Sindelfingen.

In 1916 the R.I and R.II were redesignated G.I and G.II, since they belonged to the same category as the four-engined Union G.I Albatros G.I and SSW-Forssman R-types: large in size, but engines not serviceable in flight. Records in the Daimler-Benz archives show that the R.I (G.I) and two R.II (G.II) bombers were numbered 478/15, 450/15 and 451/15 respectively. These numbers do not fit the R-plane numbering sequence, or the 1915 G-type sequence.

SPECIFICATIONS

Type: Daimler R.I

Manufacturer: Daimler-Motoren-Gesellschaft A.G., Sindelfingen

Engines: Four 160 h.p. Mercedes D.III engine

Dimensions:

Span, 21•08 m. (69 ft. 2 in.)

Length, 18•35 m. (60 ft. 2 1/2 in.)

Height, 3•80 m. (12 ft. 6 in.)

Areas: Wings, 73•62 sq. m. (792 sq. ft.)

Weights:

Empty, 2512 kg. (5538 lb.)

Loaded, 3630 kg. (8003 lb.)

Wing Loading: 49•3 kg./sq. m. (10,1 lb./sq. ft.)

Performance, Maximum Speed, 120 km.h. (74,6 m.p.h.)

Cruising Speed, 114 km.h. (70'8 m.p.h.)

Climb,

1000 m. (3281 ft.) in 16•8 mins.

1500 m. (4921 ft.) in 26•9 mins.

Ceiling, 3000 m. (9843 ft.)

Type: Daimler R.I (second version)

Manufacturer: Daimler-Motoren-Gesellschaft A.G., Sindelfingen

Engines: Four 160 h.p. Mercedes D.III engines

Dimensions: Span, 21,15 m. (69 ft. 4 in.)

Length, 18•20 m. (59 ft. 8 1/2 in.)

Height, 3•75 m. (12 ft. 3 1/2 in.)

Areas: Wings, 70•60 sq. m. (760 sq. ft.)

Weights:

Empty, 2510 kg. (5534 lb.)

Loaded, 3700 kg. (8157 lb.)

Wing Loading: 52-4 kg./sq. m. (10'7 lb./sq. ft.)

Performance: Maximum Speed, 119 km.h. (73,9 m.p.h.)

Cruising Speed, 114 km.h. (70'8 m.p.h.)

Climb,

1000 m. (3281 ft.) in 17•0 mins.

1500 m. (4921 ft.) in 28•0 min.

Ceiling, 3000 m. (9843 ft.)

Type: Daimler R.II

Manufacturer: Daimler-Motoren-Gesellschaft A.G., Sindelfingen

Engines: Four 160 h.p. Mercedes D.III engines

Dimensions: Span, 21 •26 m. (69 ft. 9 in.)

Length, 18-40 m. (60 ft. 4 in.)

Height, 3•80 m. (12 ft. 6 in.)

Areas: Wings, 74•80 sq. m. (805 sq. ft.)

Weights:

Empty, 2540 kg. (5600 lb.)

Loaded, 3680 kg. (8113 lb.)

Wing Loading: 49•3 kg.jsq. m. (10,1 lb./sq. ft.)

Performance: Maximum Speed, 123 km.h. (76-4 m.p.h.)

Cruising Speed, 120 km.h. (74'6 m.p.h.)

Climb,

1000 m. (3281 ft.) in 15•2 mins.

1500 m. (4921 ft.) in 25•0 mins.

Ceiling, 3000 m. (9843 ft.)

DFW R.I

The Deutsche Flugzeugwerke was founded in 1911 at Lindenthal near Leipzig, and prior to the war produced many successful aircraft, such as the "Mars" biplane and the "Stahl-Taube". One of the former was purchased by the Royal Naval Air Service in 1914. During the war DFW was a chief supplier of C-type aircraft to the German Army Air Service, in particular, the sturdy DFW C.V.

In 1915, at the request of Idflieg, DFW joined the R-plane programme, and its contribution was a series of clean, carefully engineered aircraft noted primarily for the successful application of a simple and straightforward solution for transmitting power from internally-mounted engines to propellers.

The DFW R.I was designed by Hermann Dorner (who in October 1916 left DFW to take the position of chief engineer at the Hannoversche Waggonfabrik, where he built the well-known Hannover two-seat fighters). Heinrich Oelerich, a renowned pre-war pilot, assisted Dorner in the design of the DFW R-planes and as technical director, he was responsible for supervising the development of the R.II series. Help was also given by Prof. H. Reissner as consultant, Dipl.Ing. Sander was the lead engineer and Oblt. Bruckmann, Denicke and Steinbeck were the test pilots. The construction of the DFW R.I 11/15 (company designation T 26) began on 1 September 1915, and was completed about a year later. The comparatively long construction period was due to a number of factors. DFW was specifically asked by Idflieg to utilize plywood for the fuselage covering, and application of this material to large curved surfaces was obviously a time-consuming process.

Furthermore, the DFW R.I and its successors were carefully engineered and showed signs of craftsmanship throughout. Finally, the effort expanded in starting production of the promising DFW C.V. observation aircraft to replace ageing Albatros, Rumpler and AEG C-types probably sapped much of the labour and materials from the R.I programme.

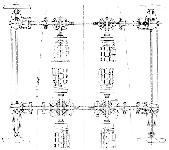

The R.I and later DFW giants were unique in that they were the only aircraft which had internally-mounted engines each driving a separate propeller. The four 220 h.p. Mercedes D.IV engines were arranged in the following manner: the forward pair of engines was mounted above and slightly ahead of the rear engines. Each forward engine was connected to a transmission shaft which ran at an angle from the fuselage to a streamlined right-angle propeller gear-box that was attached to the inner struts just below the upper wing. Similarly, the rear engine each drove a pusher propeller mounted near the trailing edge of the lower wing.

Each engine was equipped with a gear-box and clutch. The assembly formed four self-contained units completely independent of each other. The advantage of this system was that it eliminated the massive and complicated clutch-gear assemblies necessary to transfer power of three or four engines to a common drive shaft, and yet it retained all the desirable features of enclosed engines. This system proved to be efficient and mechanically sound in the long run, although it was many months before all the "bugs" were completely eliminated.

The engines were cooled initially by triangular radiators fitted between the centre-section struts. These were soon replaced by four Windhoff radiators positioned around the fuselage in the centre section gap. They were of standard pattern, very similar to those used on DFW C-types and fitted with shutters.

The construction of the R.I differed only in detail from that of the larger and better known R.II. The three-bay wooden wings were fabric covered, of equal chord throughout and had washed-out wing tips. Unbalanced ailerons were fitted to the upper wings only. The centre fuselage decking of the R.I had a markedly humped appearance because the rear decking was cut down to provide a better field of fire to the rear. A noticeable feature of both the R.I and R.II was the large semi-external gravity tank located just forward of the dorsal-gun position. Initially the biplane tail did not have a central fin, but one was added at a later date. The tailplanes differed from those on the R.II in that they were triangular in form.

The R.I made its maiden flight on 5 September 1916, and after twelve factory flights (of 8 hours total duration) it was delivered from Grosszschocher to the Army air park at Doberitz, where on 19 October 1916 it successfully completed a 2 1/2 hour military acceptance flight. During further trials at Doberitz a number of crankshaft failures occurred, more than could be properly attributed to faulty construction or poor materials of the engine. There is no doubt that the excessively long crank-shaft required by the eight in-line cylinders of the Mercedes D.IV was very sensitive to vibration, and furthermore the Mercedes D.IV was never a very successful engine. Engineers traced the failures to the high frequency vibrations, which in turn could be traced to the light and poorly reinforced engine mounts. These were replaced by greatly strengthened mounts, while universal joints and other vibration reducing devices were installed in the drive system. The span was increased slightly, requiring the addition of an extra rear strut between the wing tips. These modifications were completed by March 1917.

The R.I was now ready for operational testing, and on 30 April it was flown from Doberitz via Konigsberg to Alt-Auz, where Rfa 500 was stationed. Test flights were carried out during which it was found that the R.I could fly on two engines provided the speed was kept high and the aircraft was in light condition. At low speed with forward propellers disengaged the R.I had a tendency to stall. Three-engined flight was feasible only as long as the rudders were adjusted to counter the unequal thrust. The R.II was returned to DFW for repairs and delivered anew in May 1917.

The one and only bombing mission flown by the R.I was on 13 June 1917 when it dropped 680 kg. bombs on Schlok in retaliation for an earlier Russian attack. It carried a crew of five: two pilots, two observers and one machinist. The career of the R.I ended in September 1917. It had taken off on a bombing mission when one of it engines failed and the commander decided to return to base rather than continue on three engines. On the return flight a gear-box began to overheat badly, and a second engine had to be stopped. It was impossible to keep the heavily-loaded aircraft in the air on two engines, so the decision was made to land on a nearby artillery training field. The R.I made a good landing in spite of ground fog, but during the landing run the wheels rolled into an unseen practice trench. The aircraft broke up, and upper fuel tanks spilled petrol on to the one remaining running engine. Shortly after the crew had left the aircraft it burst into fire and the bombs exploded. One crew member, whose petrol-soaked clothes caught fire, perished.

Colour Scheme and Markings

Initially the R.I was painted a light colour overall with black Patee crosses painted directly on wingtips, fuselage and rudders. The final version sported a two-tone camouflage on the upper areas of wings and tail and on the sides and top of the fuselage. All underneath surfaces were painted a light colour. National markings consisted of the black cross Patee on a white square background, painted on the wingtips, fuselage and rudders. The serial number R.II was painted in black on the extreme front of the nose.

SPECIFICATIONS

Type: DFW R.I (first version) DFW R.I (second Version)

Manufacturer: Deutsche Flugzeugwerke G.m.b.H. Lindenthal near Leipzig

Engines: Four 220 h.p. Mercedes D.IV engines

Prop Revs: 900 r.p.m. 900 r.p.m.

Dimensions:

Span 29.5 m. (96 ft. 9 in.) 30.5 m. (100 ft.) approx.

Length 17.6 m. (57 ft. 9 in.) 17.6 m. (57 ft. 9 in.)

Height 6.0 m. (19 ft. 8 in.) 6.0 m. (19 ft. 8 in.)

Wheel diameter 1.02 m. (3 ft. 4 in.)

Wing Area 182 sq. m. (1958 sq. ft.) 186 sq. m. (2001 sq. ft.)

Weights:

Empty 5652 kg. (12,462 lb.) 6800 kg. (14,994 lb.)

Loaded 8380 kg. (18,478 lb.) 9400 kg. (20,727 lb.)

Performance:

Max speed 120 km/h. (75 m.p.h.) 120 km.h. (75 m.p.h.)

Climb to

1000 m. 10 mins.

2000 m. 25 mins.

3300 m. 53 mins.

Armament: Provision for dorsal, ventral and nose machine-gun positions

Service Use: None Eastern Front with Rfa 500

at Alt-Auz April 1917 to September 1917

DFW R.II

Flight tests had demonstrated that the R.I was endowed with adequate climb and manoeuvrability, and on this basis Idflieg placed an order on 13 November 1916 for six improved versions having a greater payload. The construction of these improved machines, designated R.II and numbered R.15/16 to R.20/16 (company designation T 26 II) was started on 10 December 1916 and differed from the R.I primarily in that the overall size was increased. The general impression is that of a simple well-designed, if somewhat bulky aircraft. The layout of the engines and the transmission system remained basically the same. The engine mountings were built of pressed steel and integral with the fuselage frames, forming a strong, compact centre-section structure which also supported wings, propeller mounts, landing gear and centre-section struts. Furthermore, the fuel tanks and bomb bay were located within this structure, thereby concentrating the stresses in a comparatively small but heavily reinforced frame-work.

Power was provided by four 260 h.p. Mercedes D.IVa engines which were coupled individually to the four propellers by bevel gears and carden shafts. Electric thermocouples allowed the pilots and flight-engineer to keep an eye on the running temperatures of gears and bearings. Cooling for the engines was by two large slab-shaped radiators, built by NFW, in the wing gap, above and to each side of the fuselage. Six fuel tanks, each of 350 litres capacity, re ted on frames below the engines, and a gravity tank of equal capacity was fitted semi-externally on the fuselage decking.

The robust fuselage consisted of four wooden main longerons spaced by wooden bulkheads and reinforced by steel tube frames and cables. The floors and catwalks were an integral part of the fuselage structure and added to its stiffness. Twisting forces were a serious problem with the long fabric-covered fuselages of the early Staaken types, but the DFW R-planes with their doped fabric-covered plywood fuselages had no difficulty in this respect. The internal layout was conventional, consisting of a nose machine-gun position, followed by a spacious cockpit for the two pilots, and a separate commandant's cockpit to the rear on the starboard side. Beneath the cockpit was the usual wireless station followed by a passageway leading through the engine-room, the roof of which was fitted with windows that could be tilted up to provide extra ventilation. Farther aft were the dorsal and ventral machine-gun positions.

The three bay wings were constructed of wood and braced internally with steel compression tubes and double cables. Interplane struts were faired steel tubes, and all wing bracing was double cable. The lower wings incorporated dihedral and were cut away at their trailing edges to clear the pusher propellers. Balanced ailerons were fitted to the upper planes only. The empennage consisted of a biplane tail; the central fin and lower tailplane were an integral part of the fuselage and both tailplanes were fitted with elevators. The king posts of the outboard rudders doubled as rear tail struts. All tail control surfaces were balanced.

The first R.II (R.15) made its maiden flight on 17 September 1917 successfully in all respects save one; serious vibrations were still very much in evidence in spite of greatly strengthened engine mounts. The problem lay in the high revolutions of the outrigger transmission shafts, and this was solved by encasing the shafts within stiffener tubes with the help of ball-race.